Lessons From the Field – 3D Printed Face Masks

In the fight against COVID-19, everyone has been encouraged to use a face mask to reduce the risk of transmitting the virus. With this incredible new demand upon the PPE supply chain, there have been reports that even hospitals are experiencing shortages of the equipment necessary to keep their workers protected. This presents a unique opportunity for the additive manufacturing industry to help the healthcare industry. Our team has supported over 40 organizations in their effort to print face masks and we’d like to share some of the insights we’ve gained.

Before we dive in, it’s important to establish some quick background terminology. There are two common types of respiratory safety devices that you will see. We will refer to them as masks and respirators. Masks (aka “surgical masks” or “face masks”) are flexible cloth coverings that are held in front of the individual’s nose and mouth. These are intended to block droplets of fluid that become airborne when you talk or sneeze. Respirators on the other hand, usually include a hard shell and an industry-rated filtration medium. These are intended to actively filter the incoming air to remove harmful particles. Refer to the comparison table below for more information. For this article, we will be focusing on face masks only, and we will address respirator-style devices in another post in our COVID-19 blog series.

Select an Approved Design

In this post, we focus on two face mask frames that are available on the NIH Print Exchange and designated “Community Use”. The NIH describes this designation to “indicate designs that are suitable for workers in grocery stores, restaurants, law enforcement, or in general use interacting with others. Community use designs have been tested for fit, efficiency, and reliability when the wearer is not in direct contact with a person diagnosed or suspected of having COVID-19.” The CEG Extreme and the GE Additive Community Frame are the only two face mask frames to have received this designation.

In this post, we focus on two face mask frames that are available on the NIH Print Exchange and designated “Community Use”. The NIH describes this designation to “indicate designs that are suitable for workers in grocery stores, restaurants, law enforcement, or in general use interacting with others. Community use designs have been tested for fit, efficiency, and reliability when the wearer is not in direct contact with a person diagnosed or suspected of having COVID-19.” The CEG Extreme and the GE Additive Community Frame are the only two face mask frames to have received this designation.

The GE Additive face mask frame is available on the NIH Print Exchange in large, medium, and small sizes. Another way to alter the size of the masks is within the model settings window. Read more about precisely scaling models here.

Source your Materials

Face mask frames are designed to have as few parts as possible and are ideal for mass production on almost any 3D printer. Normal components include the 3D printed frame, fabric material, and strapping.

Face mask frames are designed to have as few parts as possible and are ideal for mass production on almost any 3D printer. Normal components include the 3D printed frame, fabric material, and strapping.

We’ve found that the frames are best printed in PLA and PETG. PETG is preferable due to its durability and flexibility – ultimately proving to be more comfortable when the face mask is worn for extended periods of time. If you haven’t printed in these materials before, visit our Ultimate 3D Printing Materials Guide to learn more and get started.

The CDC advises that almost any kind of cloth can be used as a mask material. Some of their suggestions include sections of t-shirts, pillowcases, or bandanas. With your materials gathered, it’s time to start printing the face mask frames.

Optimize your Print Settings

Below are several tips our team has found to optimize the printing of the face mask frame.

-

Increase the Number of Perimeters

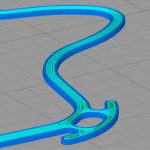

On thin parts, like these frames, it’s important to make sure they’re as strong as possible. One way this can be achieved by increasing the number of perimeters to 4 or more. With additional perimeters, the frame will not require infill. Read more about thin walls and small features in this in-depth article.

On thin parts, like these frames, it’s important to make sure they’re as strong as possible. One way this can be achieved by increasing the number of perimeters to 4 or more. With additional perimeters, the frame will not require infill. Read more about thin walls and small features in this in-depth article.

-

Make Small Parts Solid

When printing the CEG Extreme frame mask, the fabric pegs have a tendency to shear off during use.

When printing the CEG Extreme frame mask, the fabric pegs have a tendency to shear off during use.

- To make these pegs stronger, use the variable settings wizard to set the infill percentage to 100% at the start of the peg. Read more about how to use the variable settings wizard here.

- Due to the incredibly small size of these pegs, you may want to lower the Minimum Infill Length to 3 mm or less to make sure the pegs are completely filled.

Putting your Print to Use

Once you have completed your print, it’s time to assemble and prepare your face mask.

-

Cut the Material

Once you have completed your print, cut the fabric material larger than the overall perimeter of the face mask frame. This enables the material to billow out from your face and give your mouth room to move underneath the face mask. Experimenting with the amount of excess material will be necessary for a comfortable fit.

-

Testing the Fit

After the material and straps have been attached, put on the fully assembled face mask. The mask should fit comfortably. The mask is designed to sit under the chin and follow the contours of your face up to the bridge of your nose. There shouldn’t be any gaps or distortions of the mask frame. If there are any gaps or distortions of the mask frame try a different size or scale the model to ensure a better fit.

-

Disinfect

If you intend to donate the mask to someone else, make sure you disinfect the completed assembly first. There are many ways to disinfect, one of the most accessible options is bleach. Submerge the 3D printed face mask frame in a 10% bleach solution for 5 minutes to remove any contaminants. The CDC has compiled helpful tips on this page.

-

Distribution

One of the final challenges after completing your face mask is getting it into the hands of the men and women that need it. If you are a business or non-profit that can produce NIH approved products, registration on their site is the first step you should take to distribute your face masks. If you are an individual, a nearby city most likely has an established group distributing PPE – a quick Google search should point you in the right direction.

During this challenging time continue to check back frequently for updates on how you can help in the fight against COVID-19. The Simplify3D team will continue to provide software support and be available to answer any questions.

Are you helping in the fight against COVID-19 using 3D printing technology? If you have participated in 3D printing efforts to support health care workers or know of new ways additive manufacturing is being used to combat COVID-19, please share your story with us at stories@simplify3d.com.