Ultimate 3D Printing Materials Guide

After over a year of research, countless filament spools, and hundreds of hours of printing, our team is proud to present the Ultimate 3D Printing Materials Guide. Covering over a dozen of the most popular materials in use today, this guide will help you select the best material for your next project or improve the quality of your prints with tips from our experts. Use the tags below to quickly sort the materials based on their characteristics, or view our extensive Filament Properties Table for a detailed side-by-side comparison. Once you have selected a material, view a detailed article with pros and cons, hardware requirements, best practices, pro-tips, example projects and more! Whether you’re new to 3D printing or an advanced user looking to experiment with a new material, this guide has everything you need to make the most of your next project.

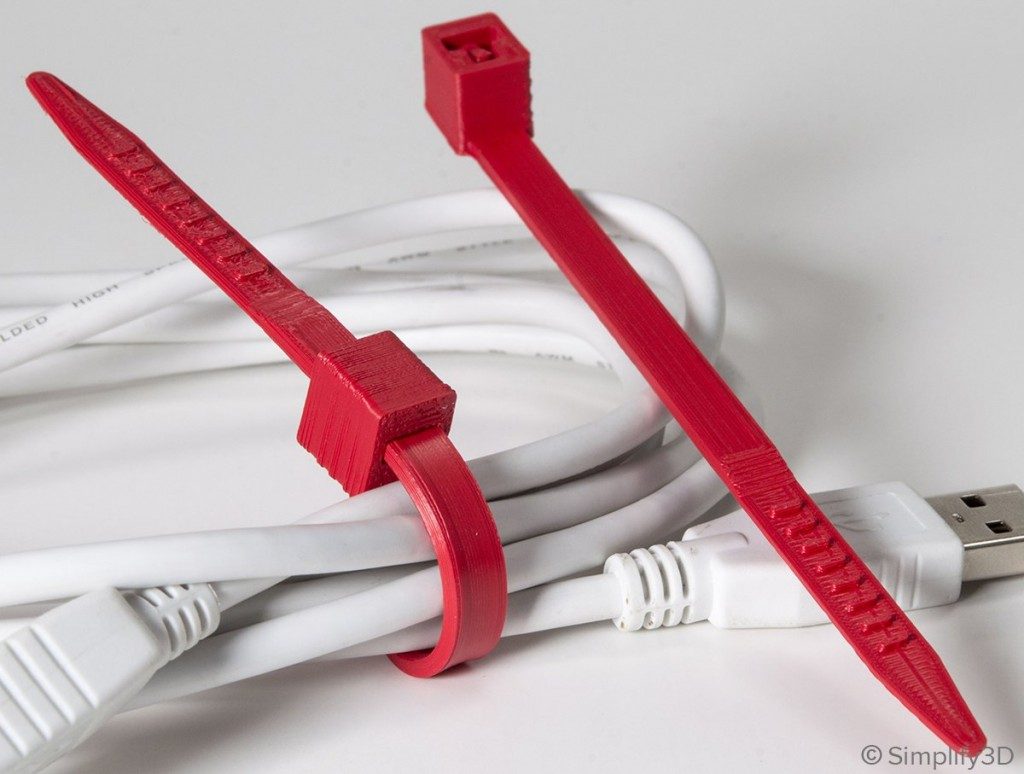

Select one of the materials below to get started. Each image highlights a sample project that was printed with that material.

- All

- Chemically Resistant

- Composite

- Dissolvable

- Elastic

- Fatigue Resistant

- Flexible

- Heat Resistant

- Heated Bed Not Required

- Impact Resistant

- Rigid

- Soft

- UV Resistant

- Water Resistant