Print Quality Troubleshooting Guide

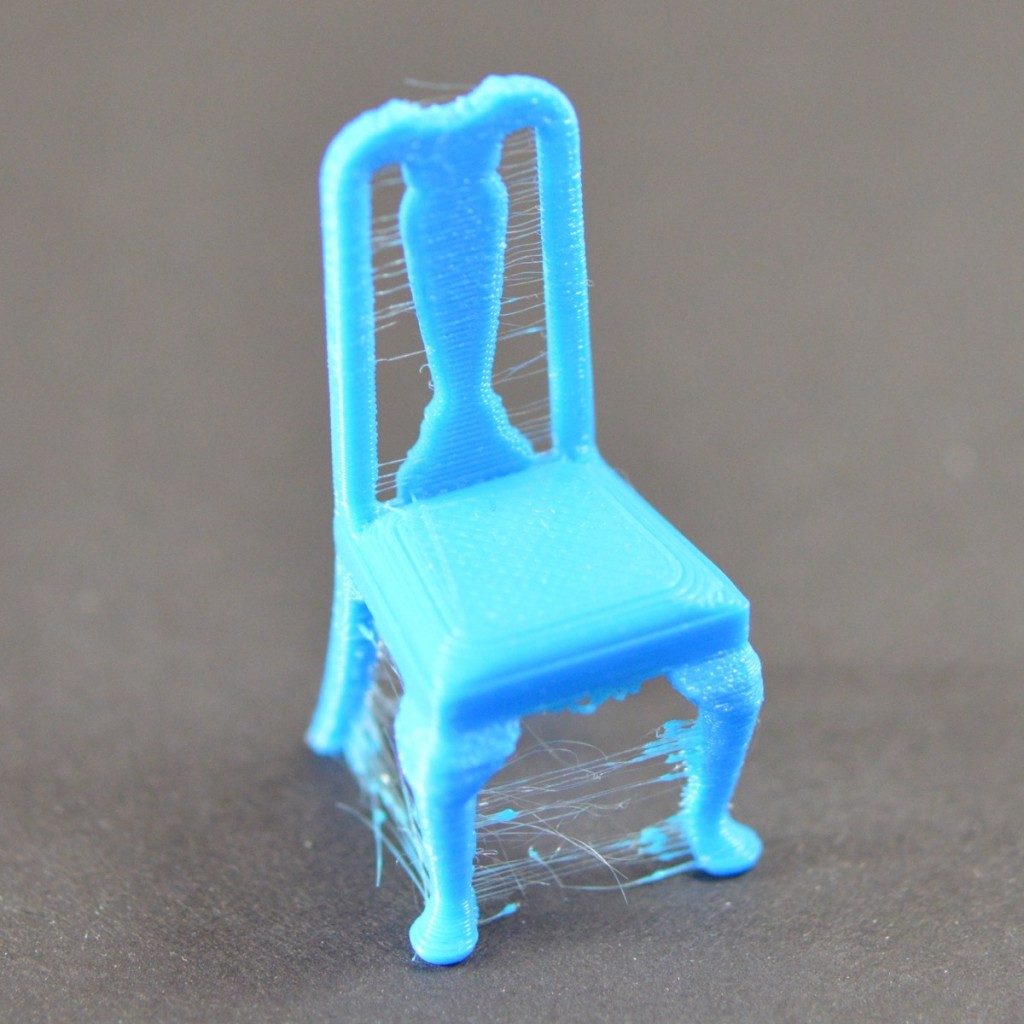

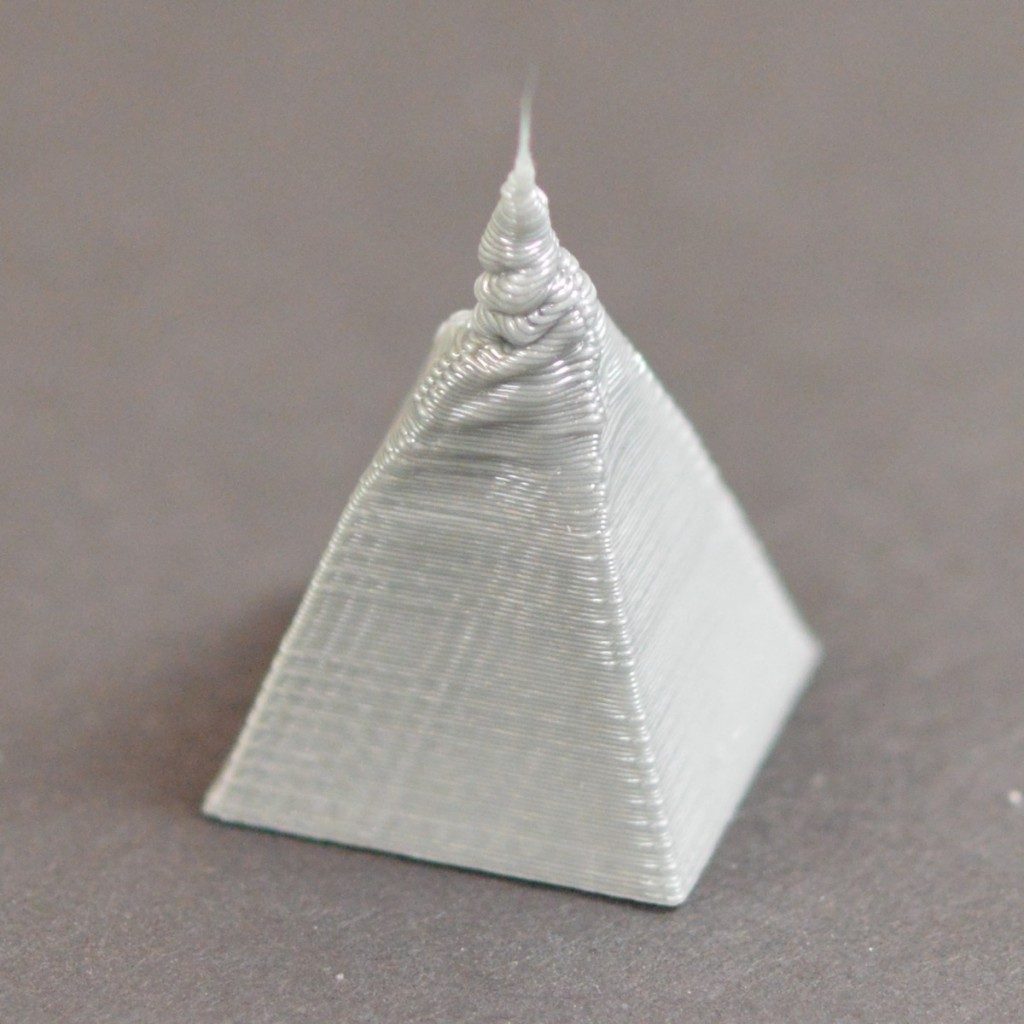

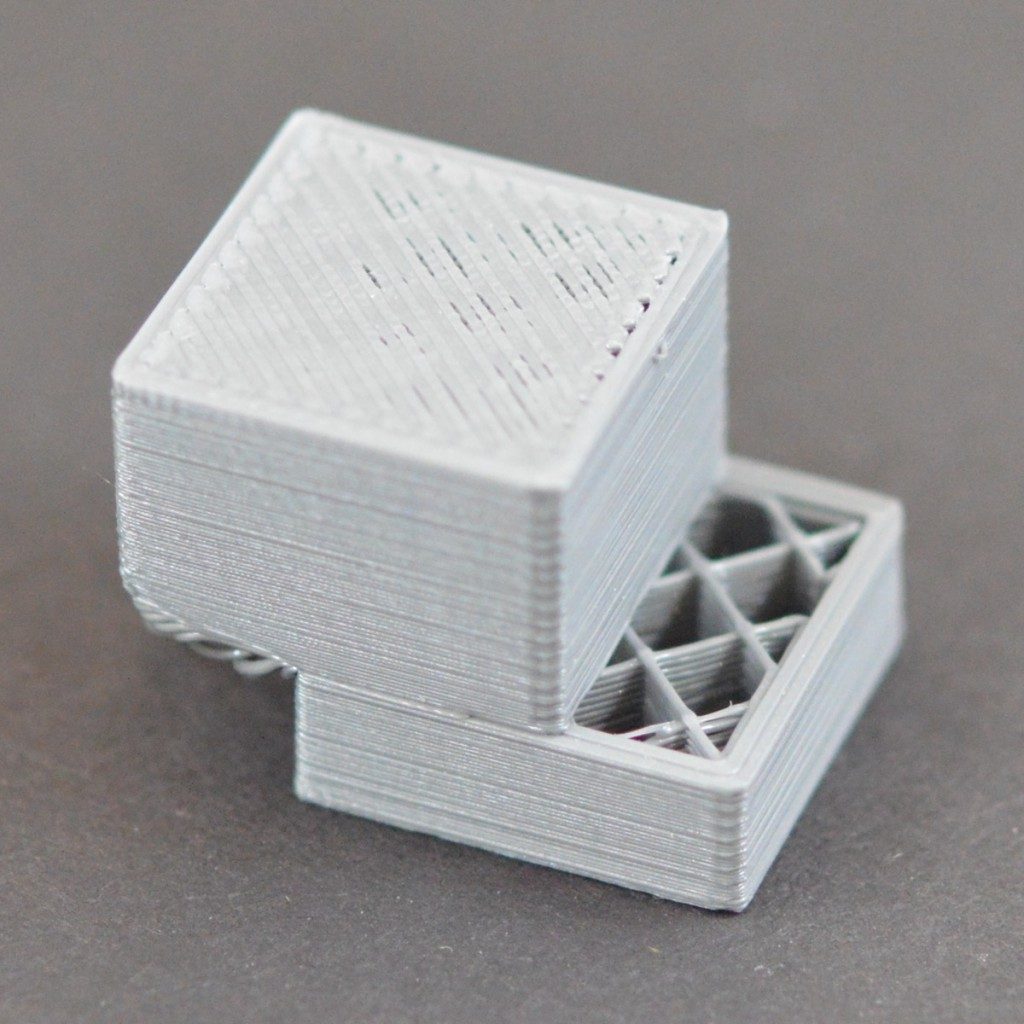

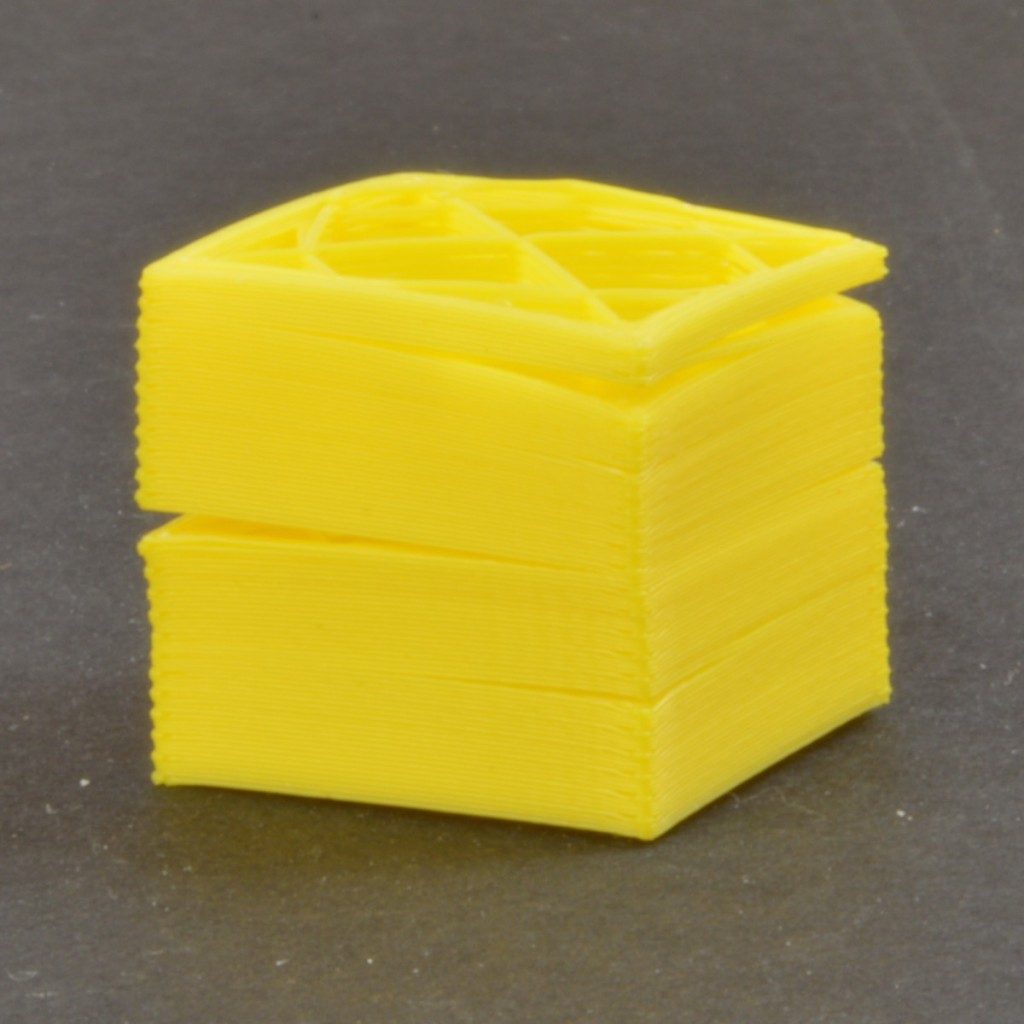

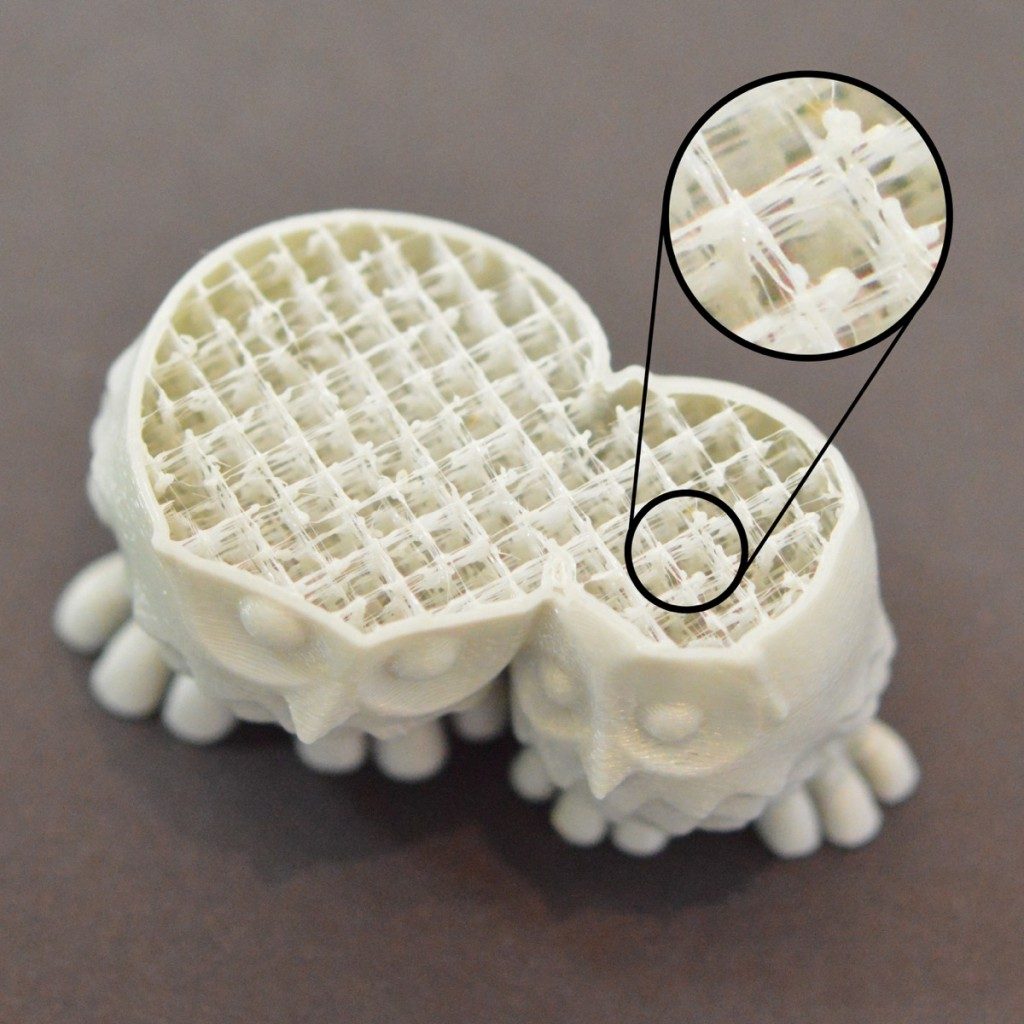

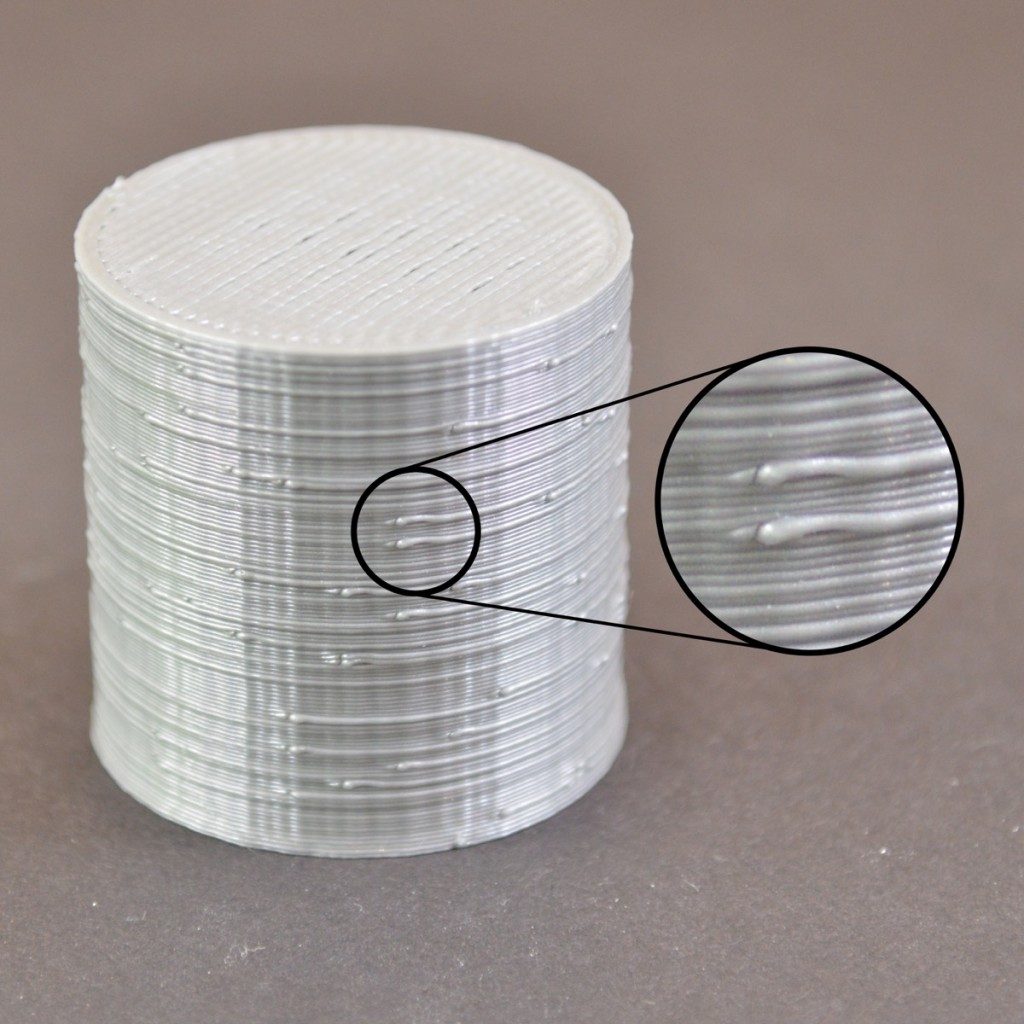

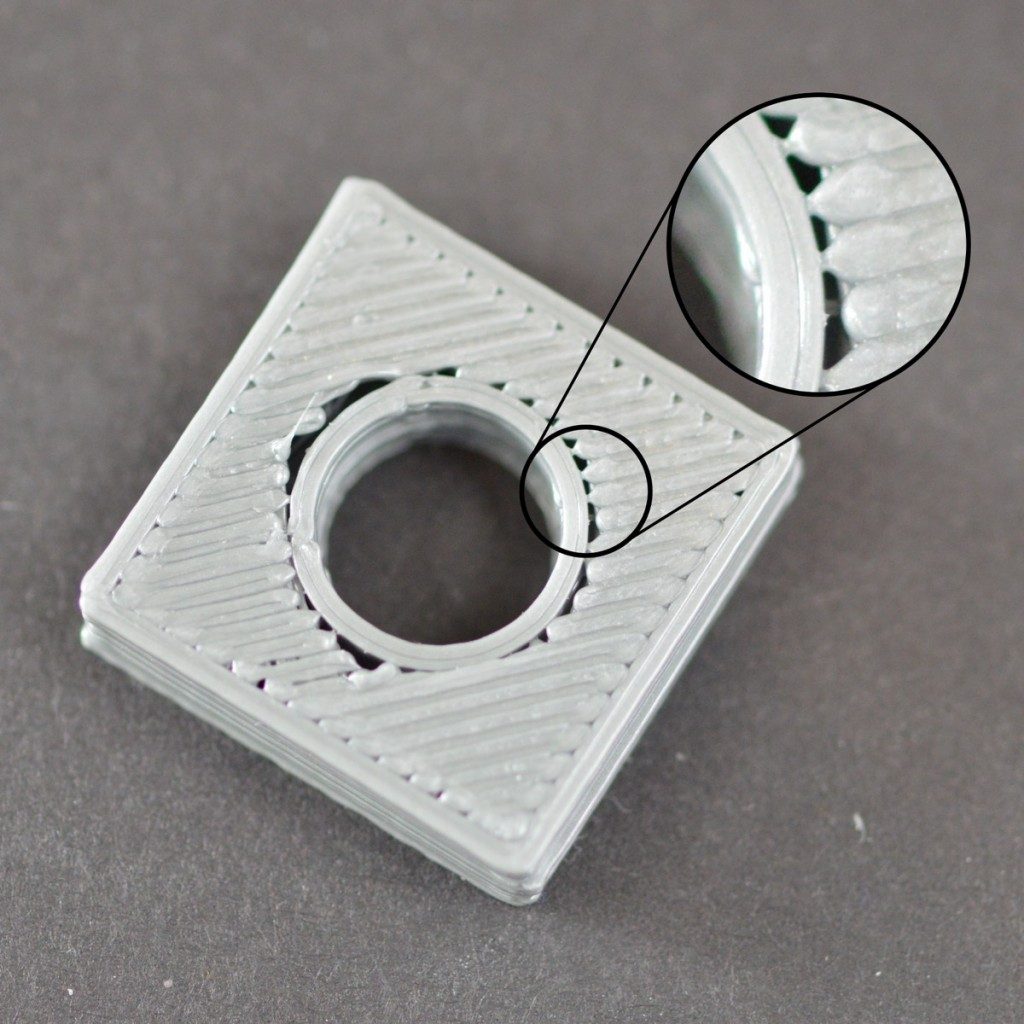

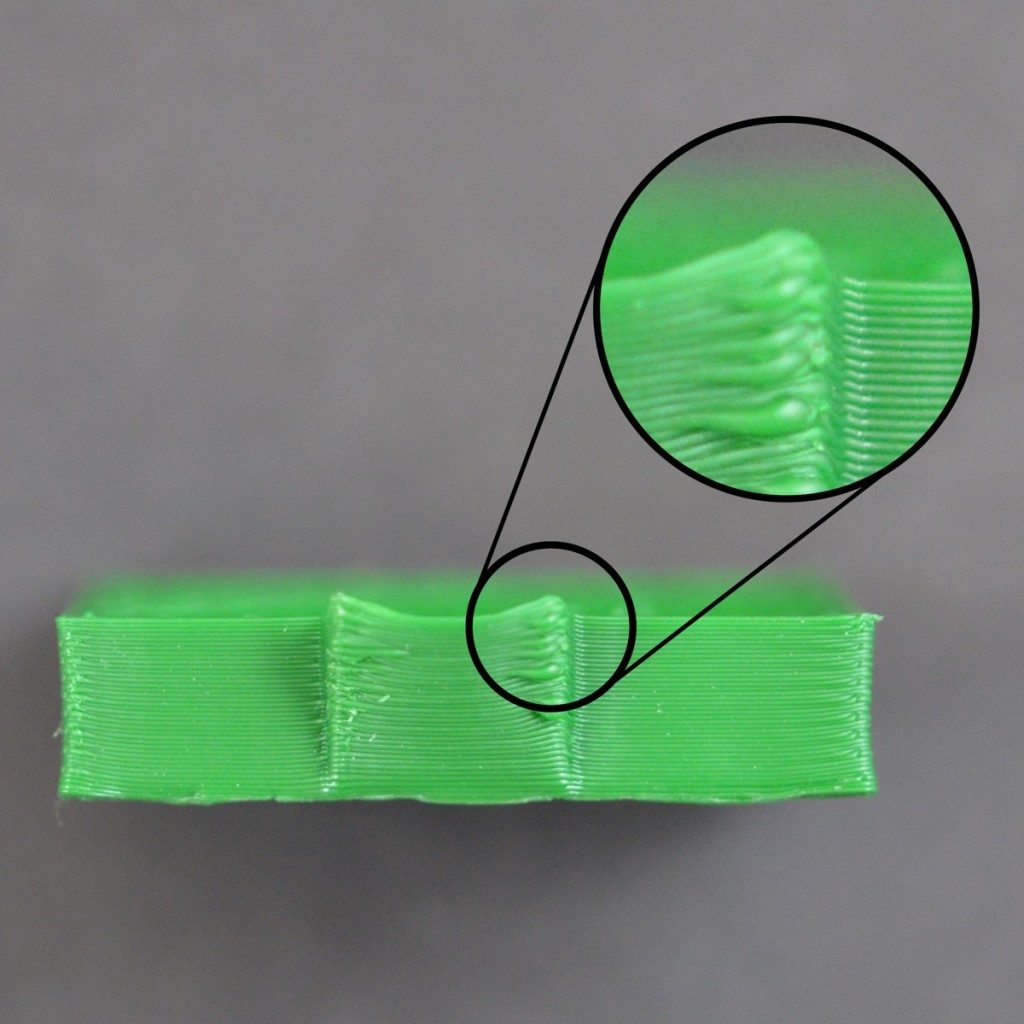

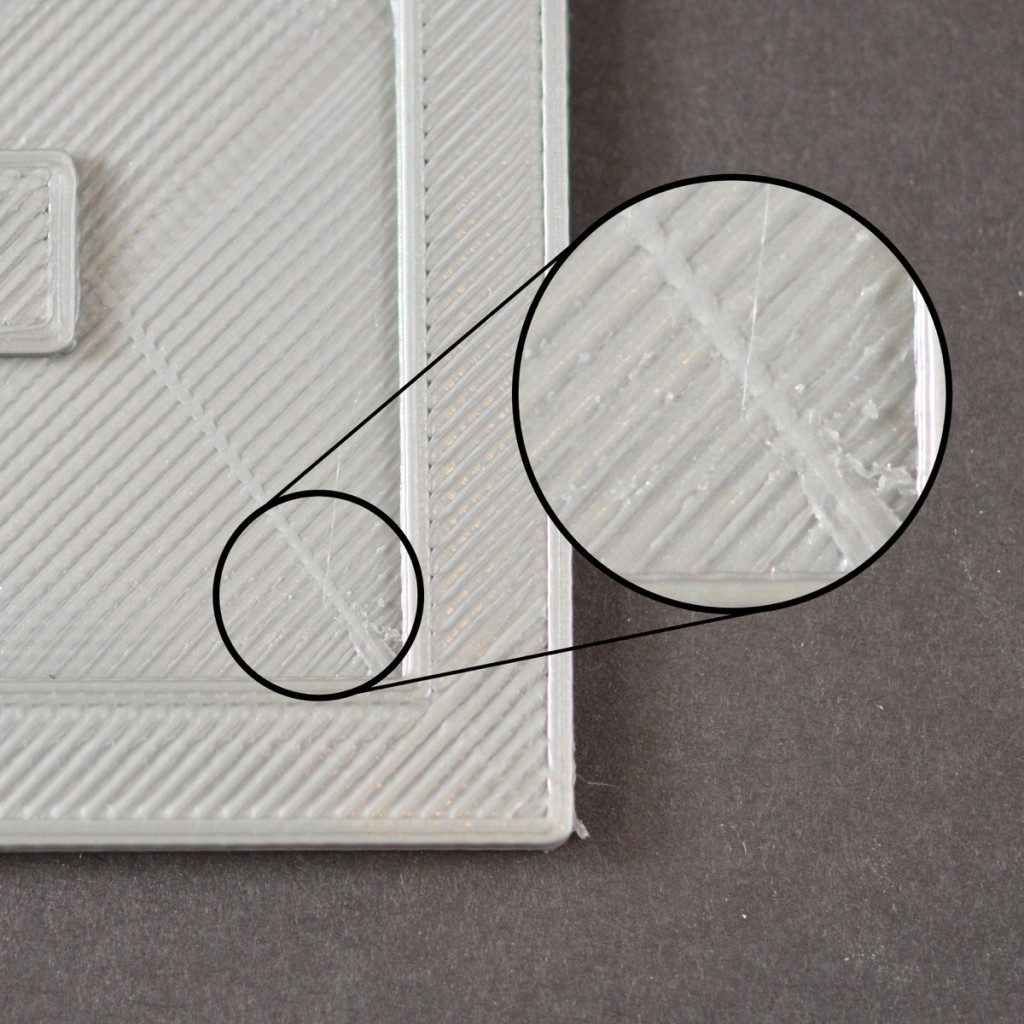

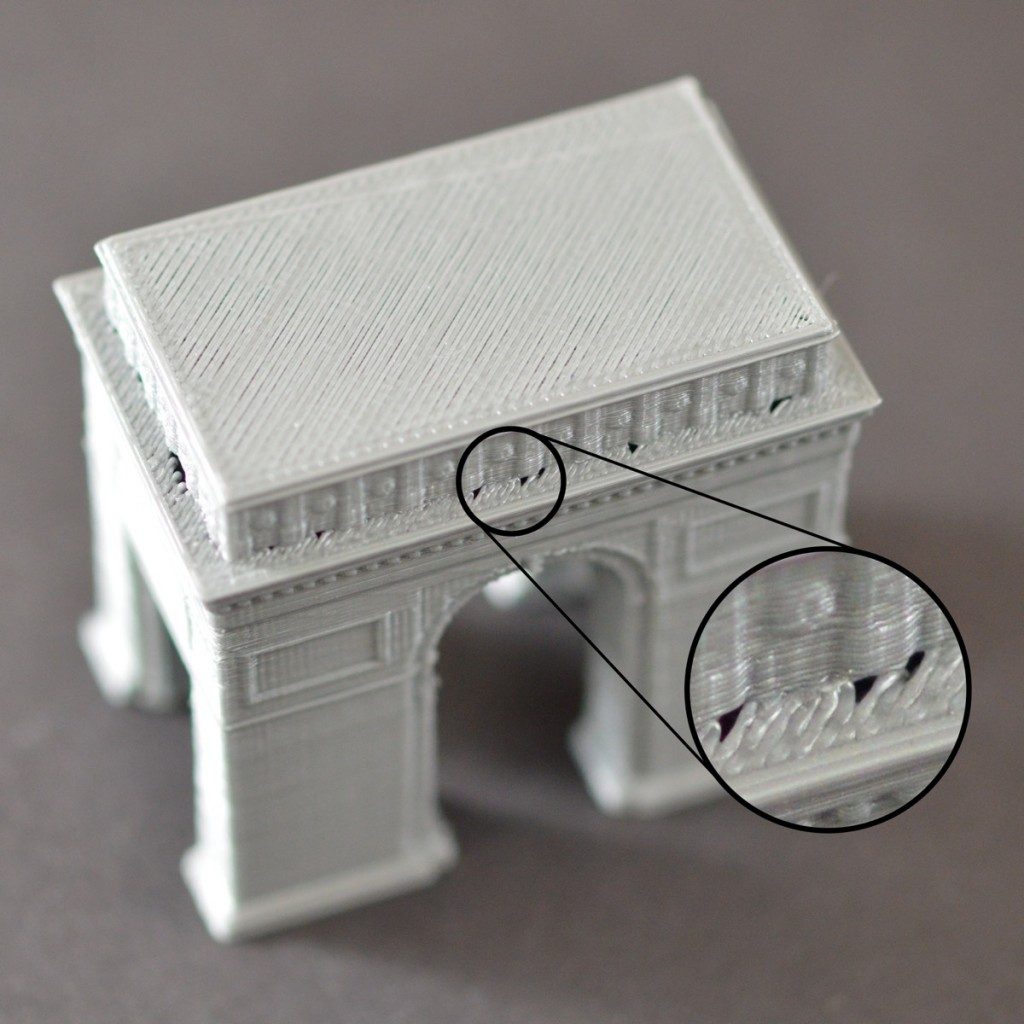

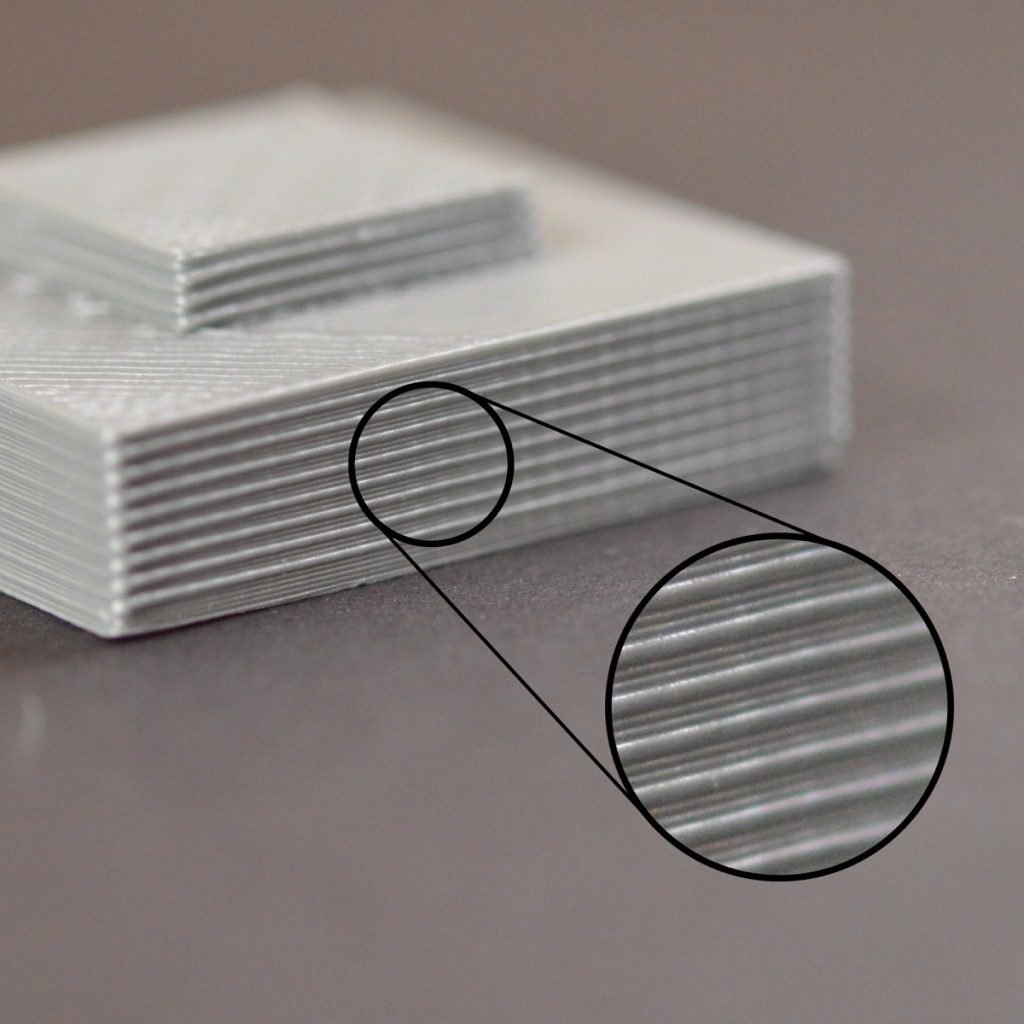

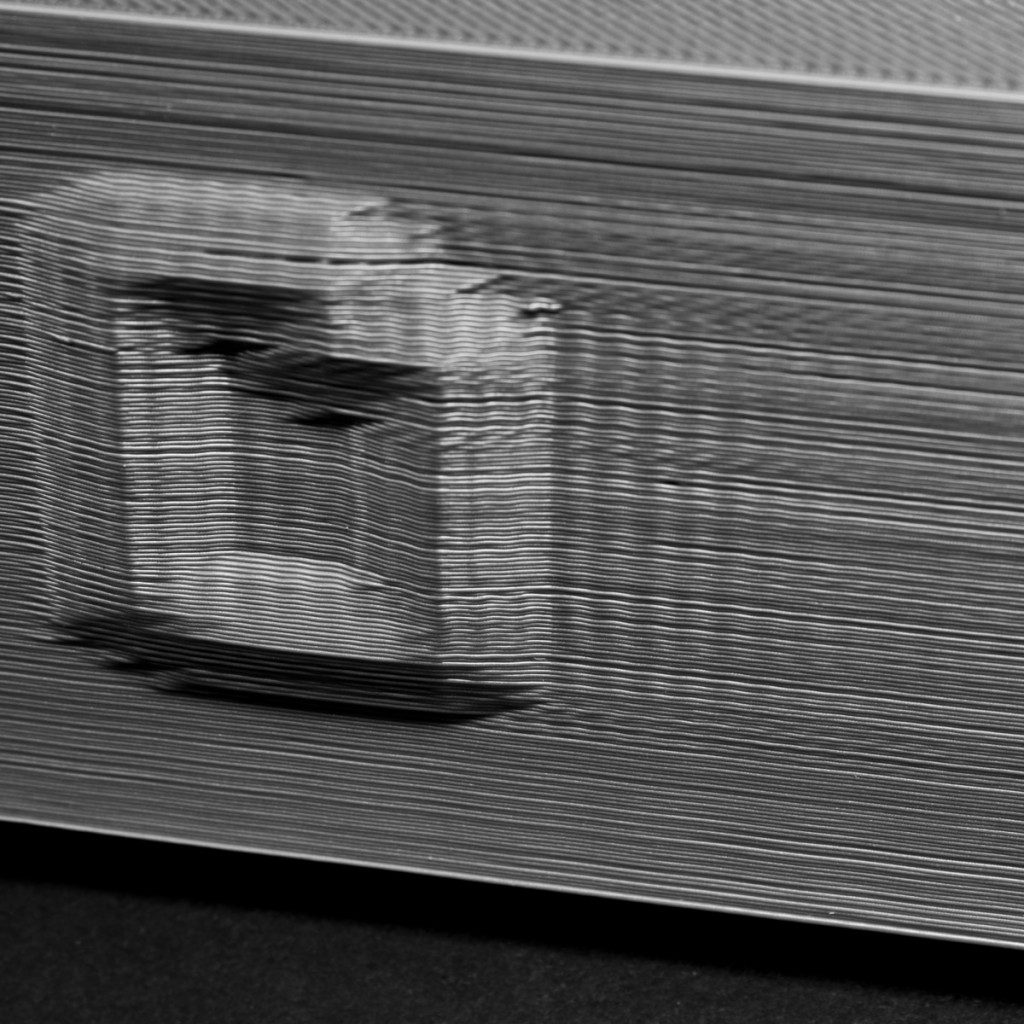

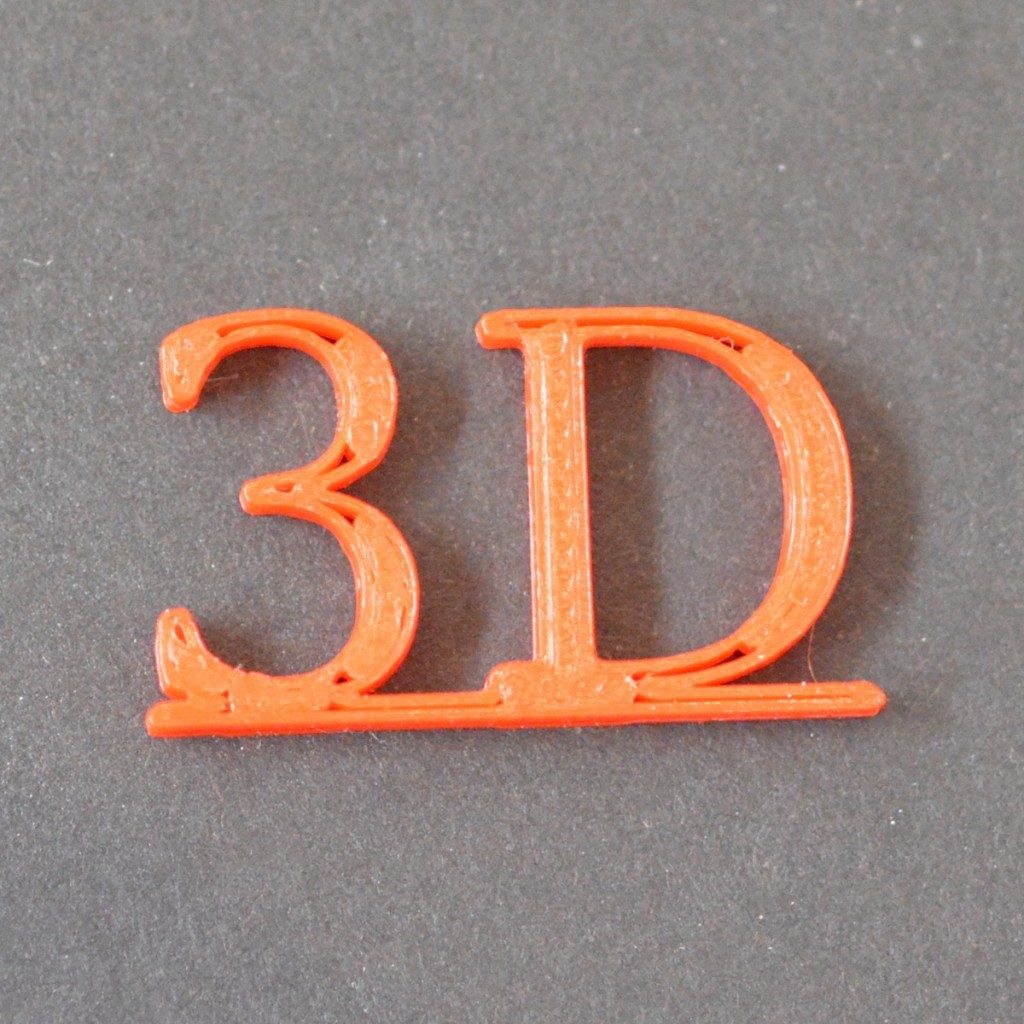

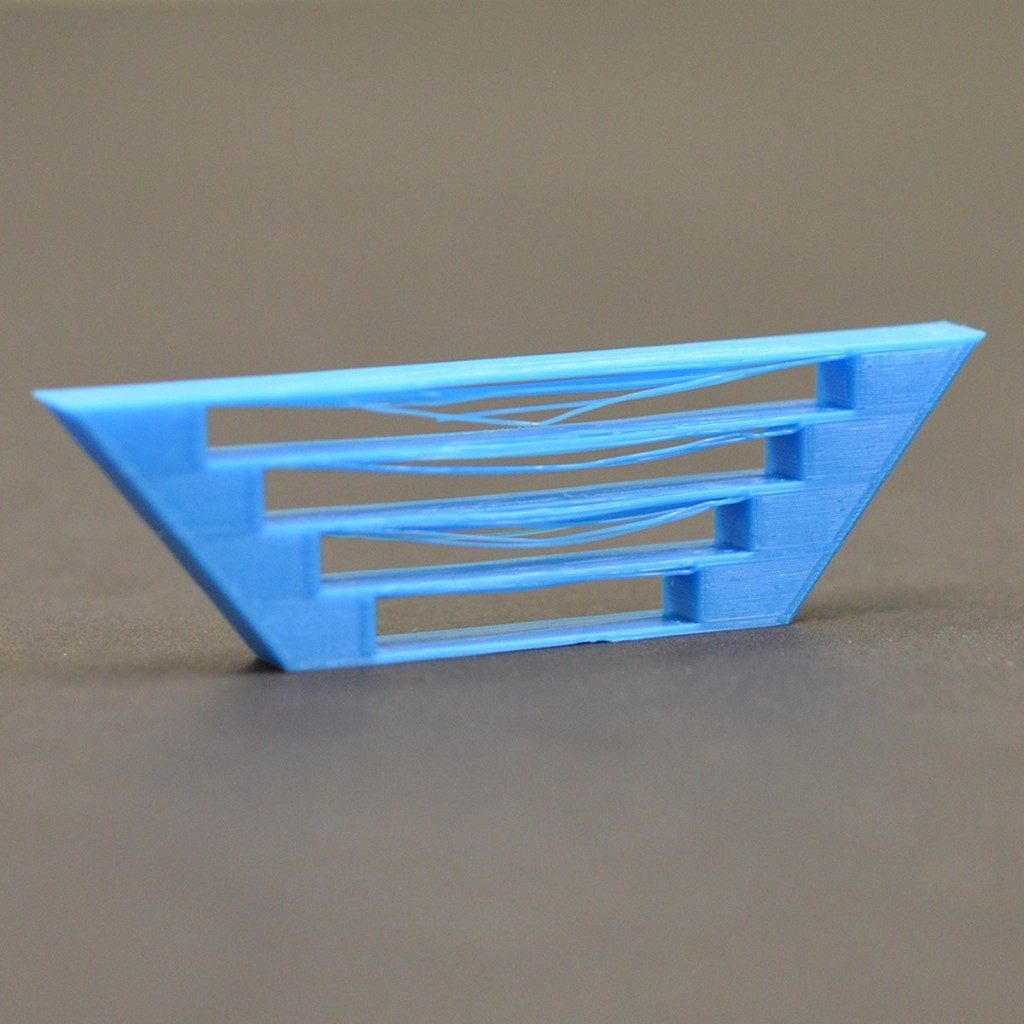

This guide is a great place to start if you are trying to improve the quality of your 3D printed parts. We have compiled an extensive list of the most common 3D printing issues along with the software settings that you can use to solve them. Best of all, the guide uses a large collection of real-world images to make each issue easy to identify when examining your own 3D printed parts. So let’s get started!

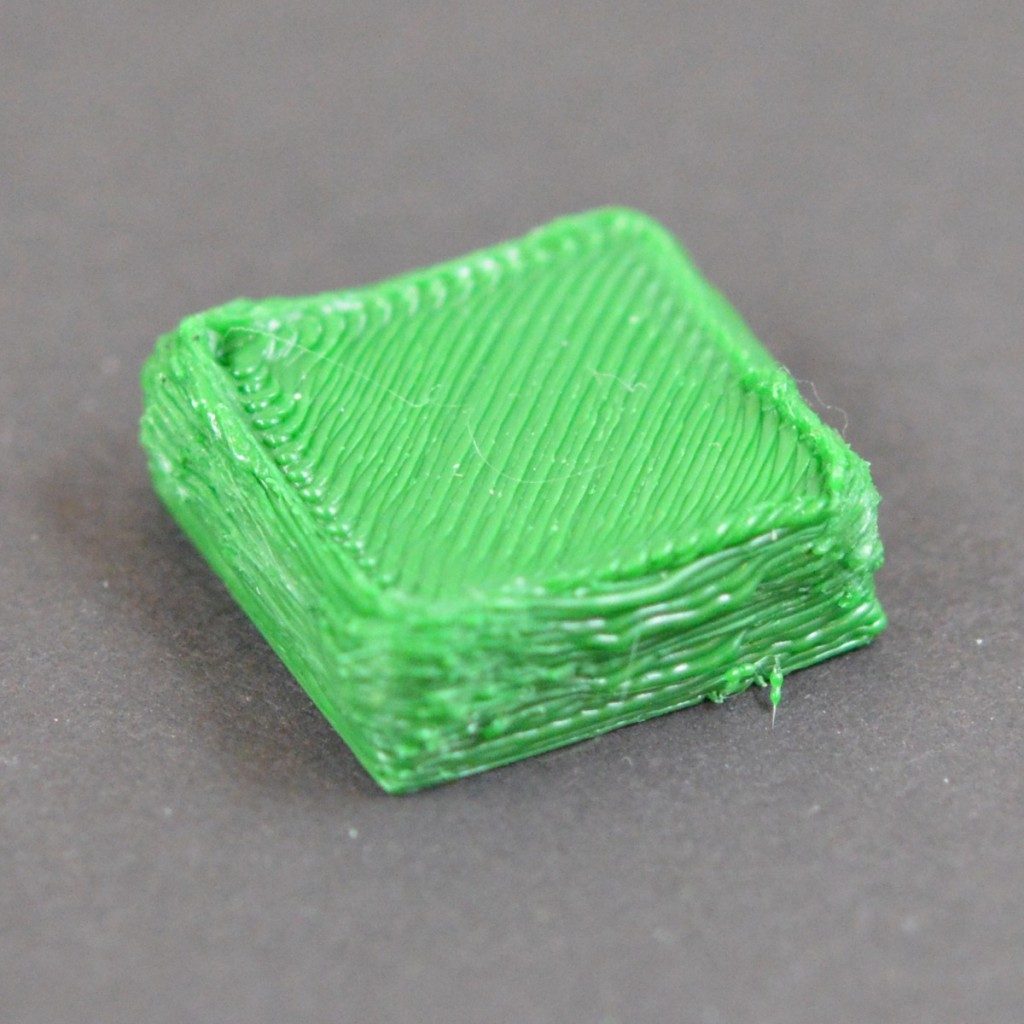

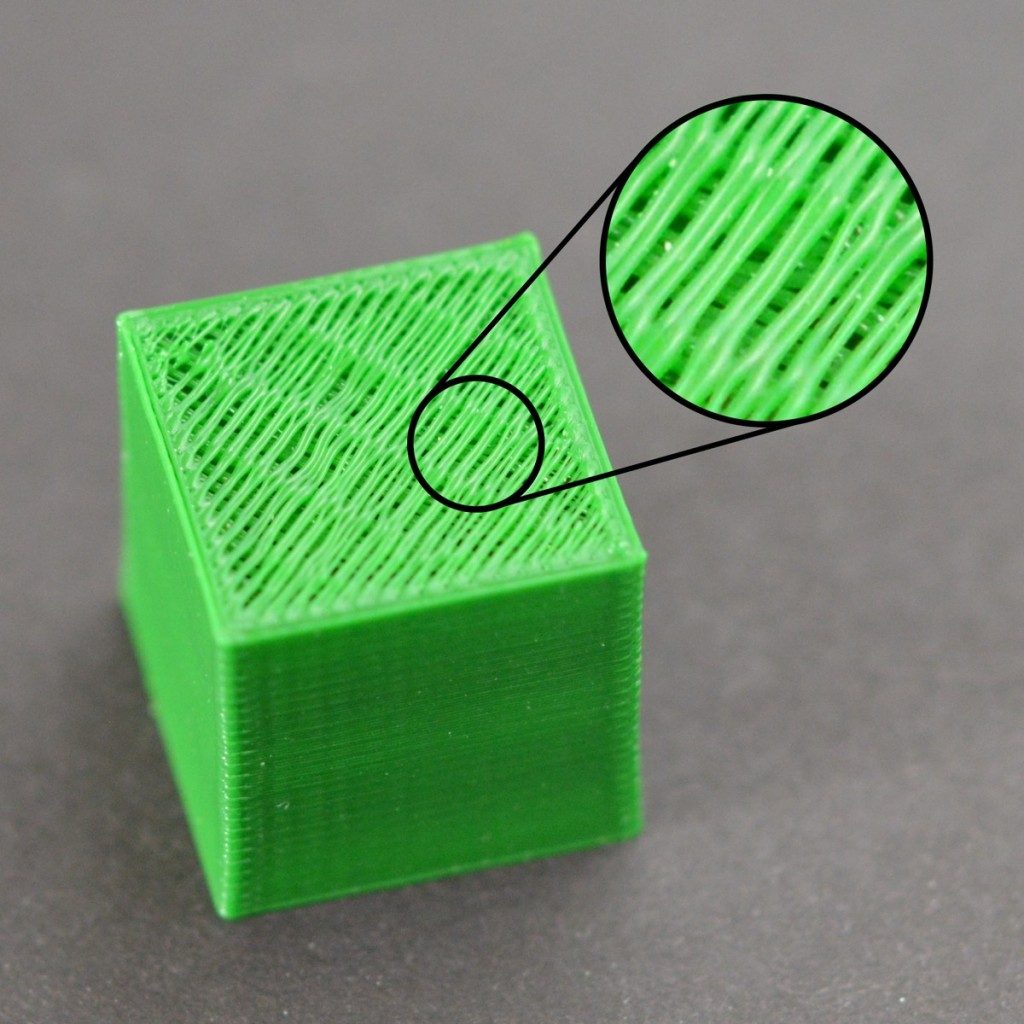

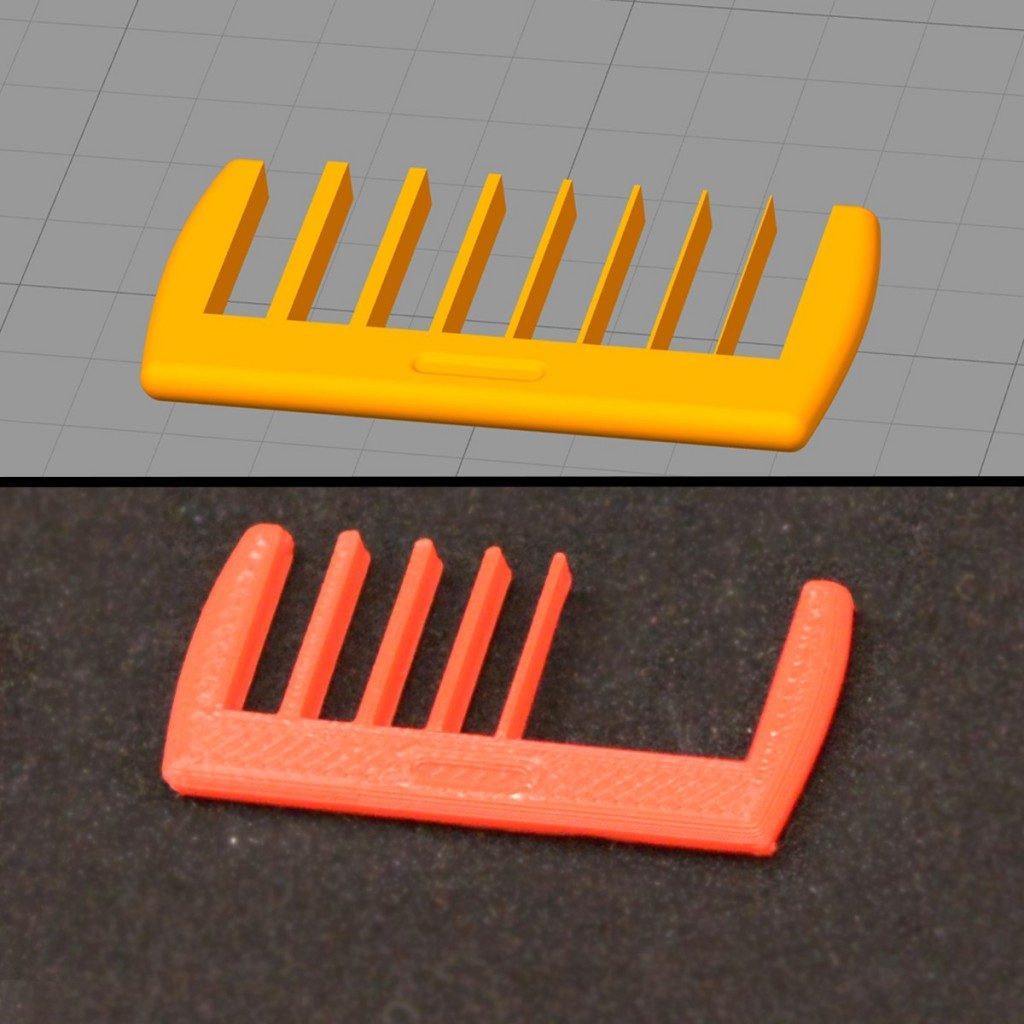

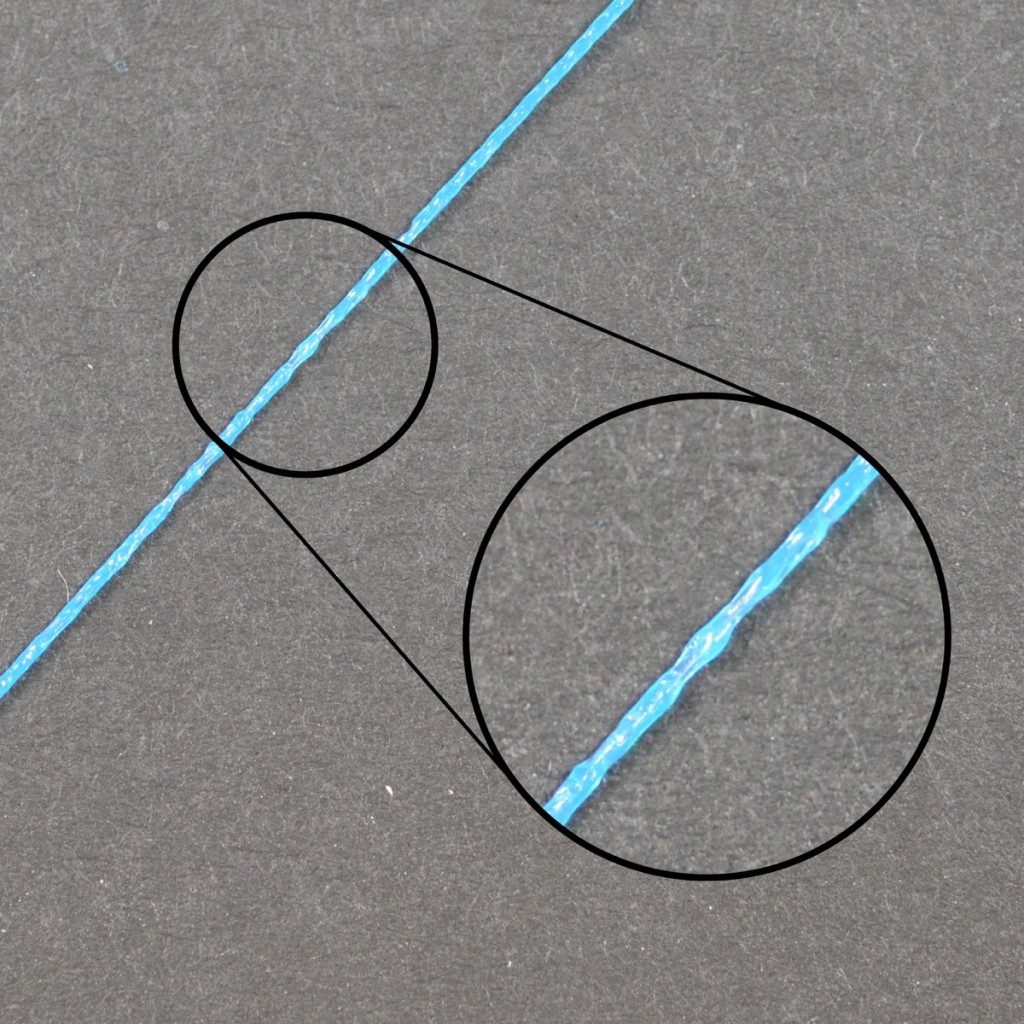

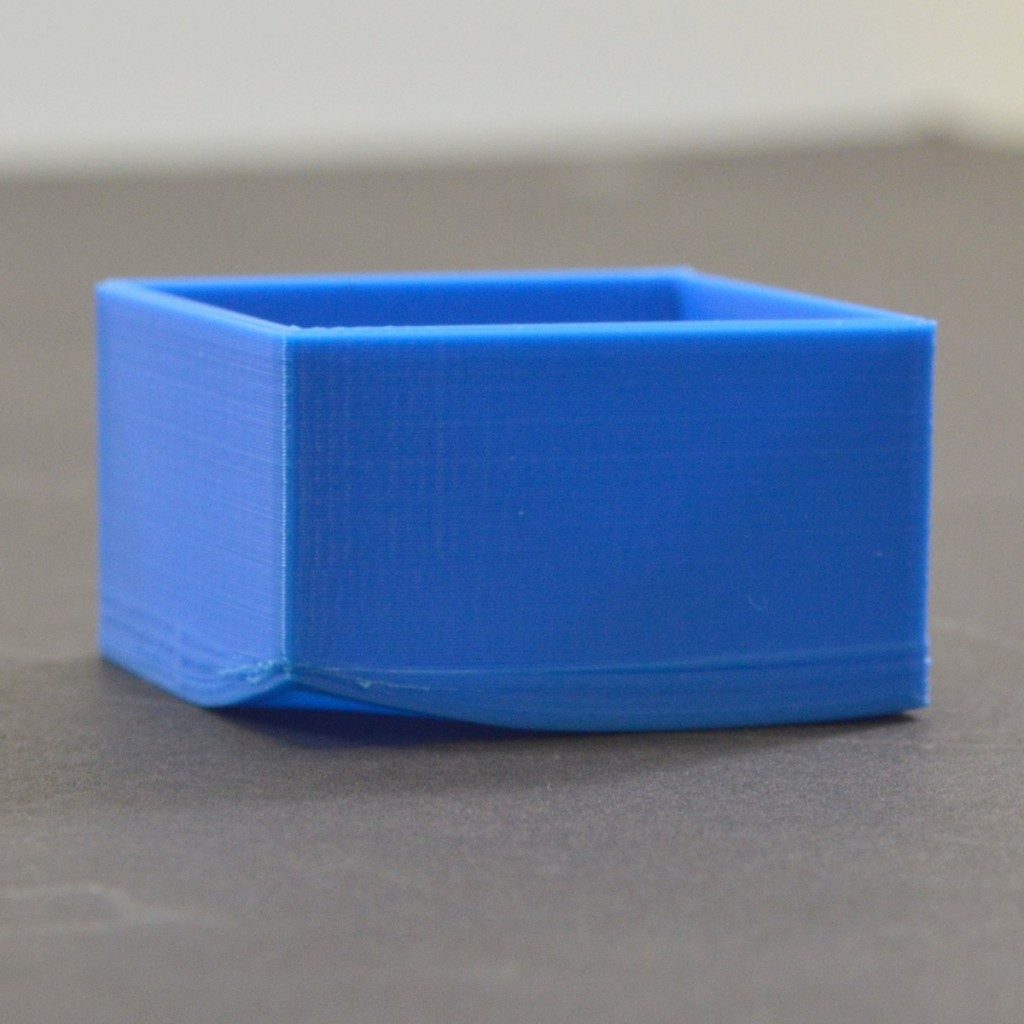

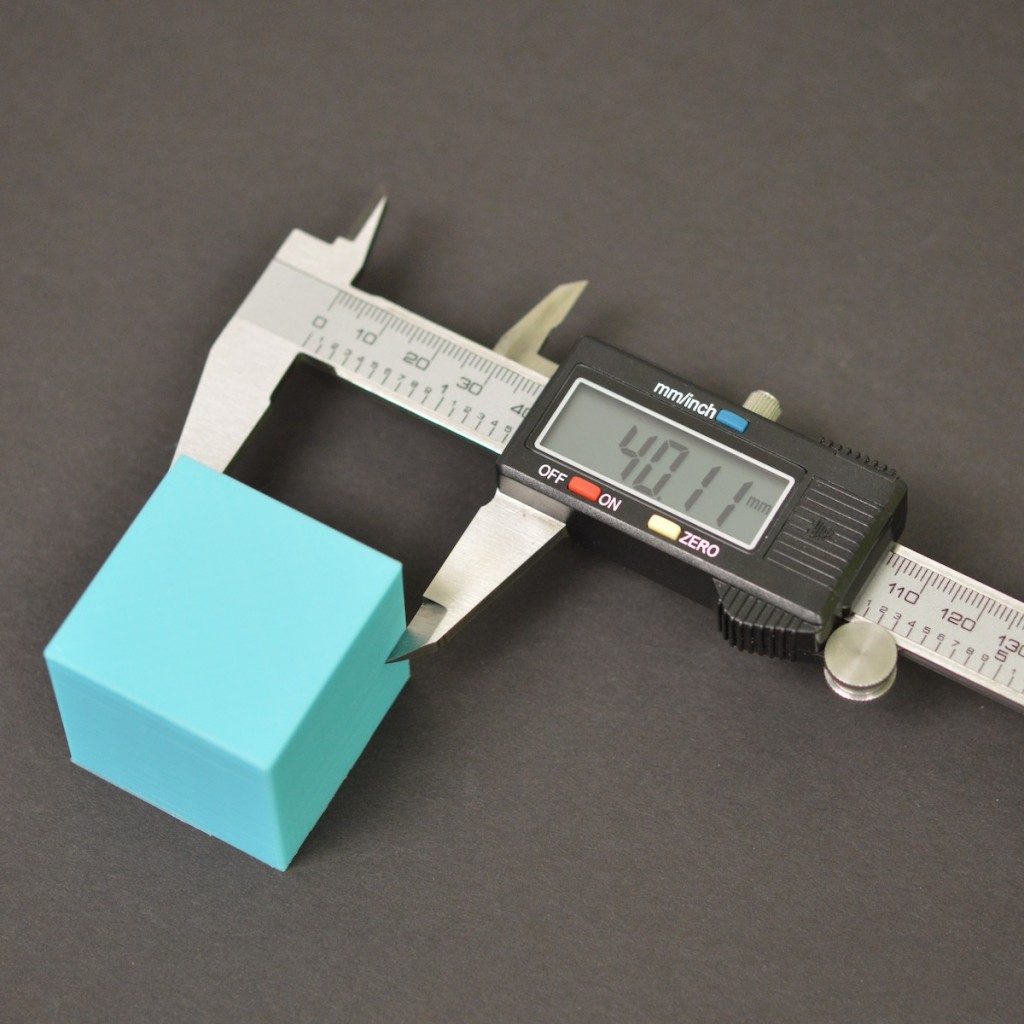

Thumbnail Overview

Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3D printed parts. You can click on the thumbnail to jump that that portion of the guide for immediate recommendations on how to resolve the issue. If you are not able to locate your issues from the thumbnails, feel free to scroll down and read through each section of the guide in more detail. There are plenty of useful tips to learn that can help improve your 3D printed results!