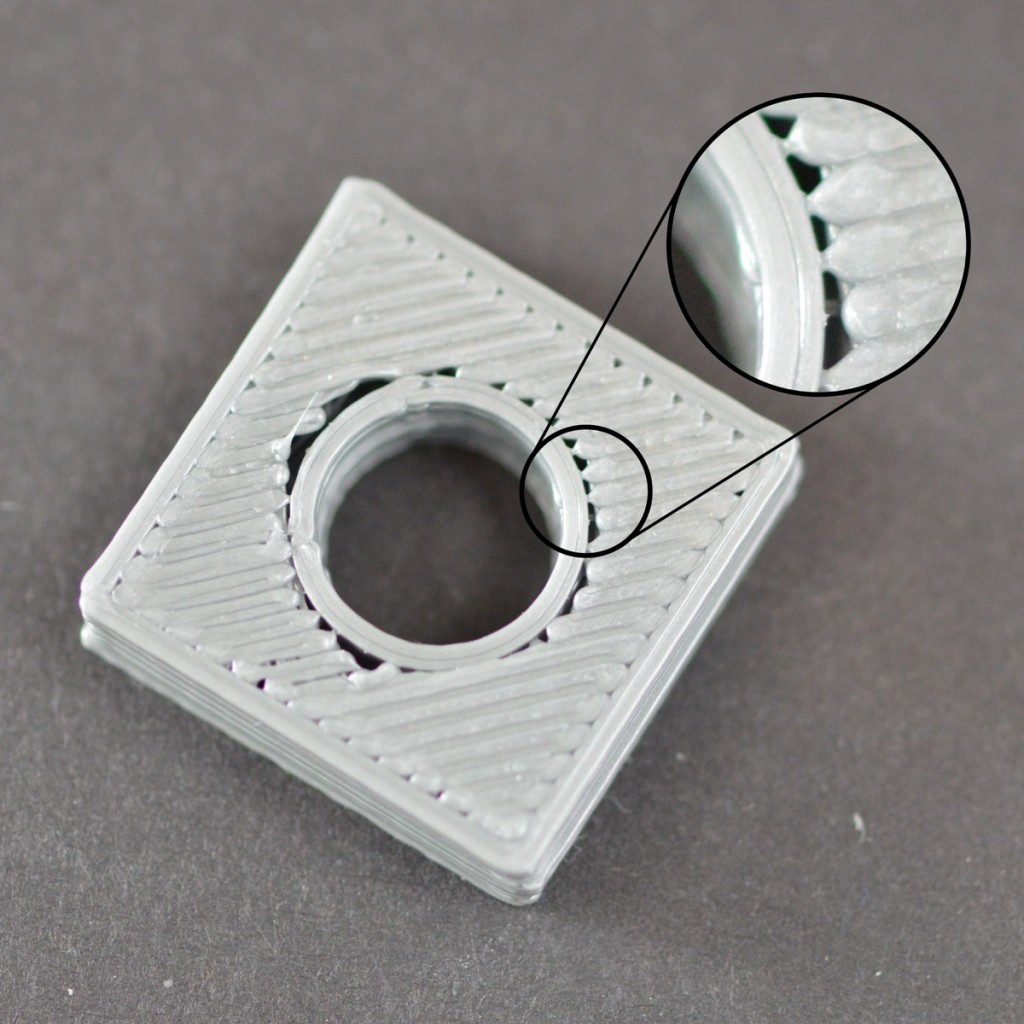

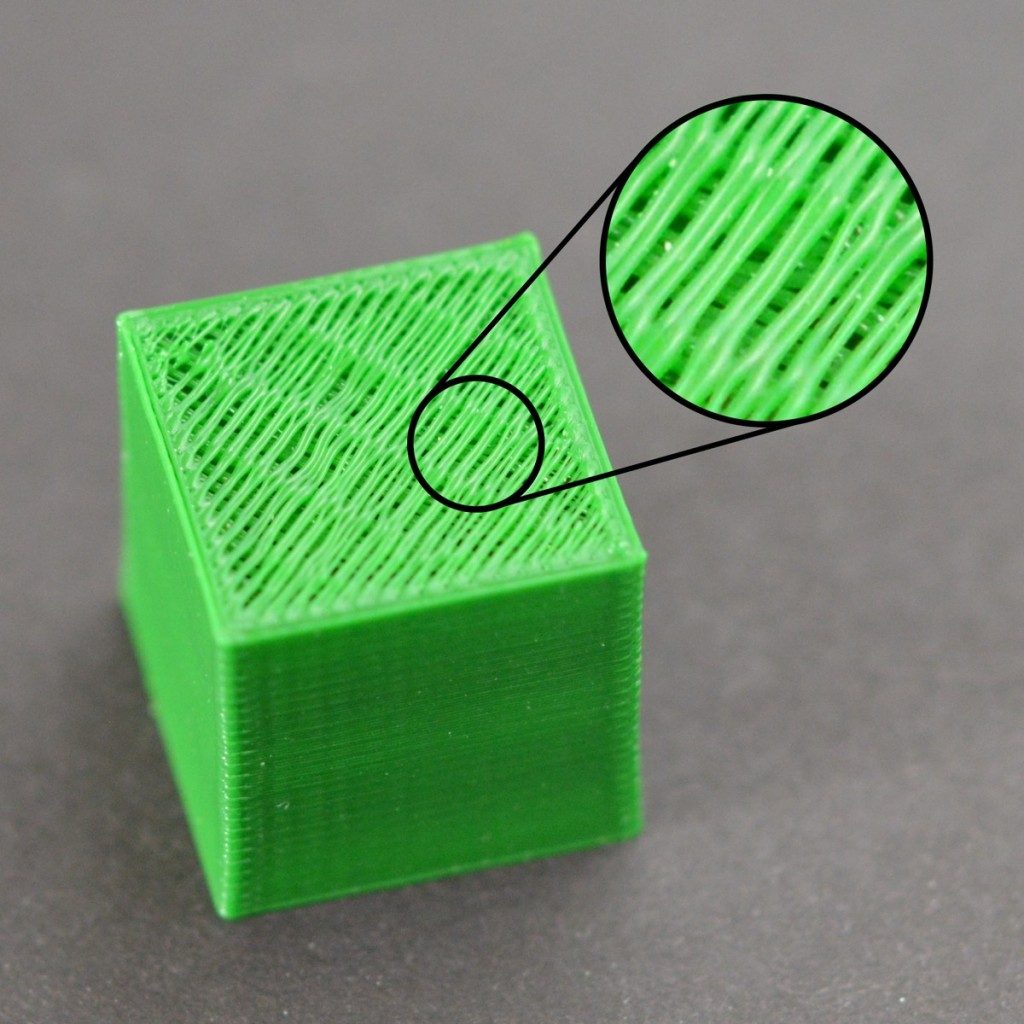

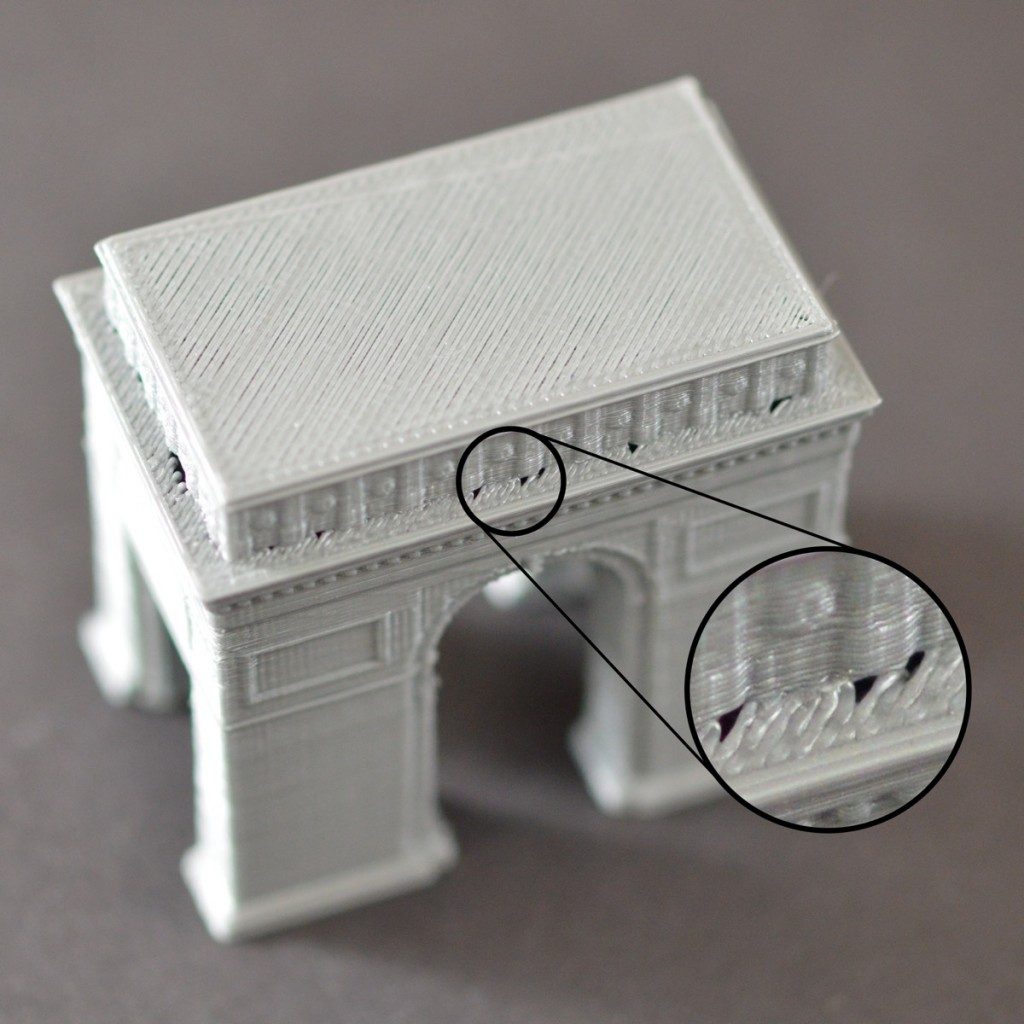

Gaps Between Infill and Outline

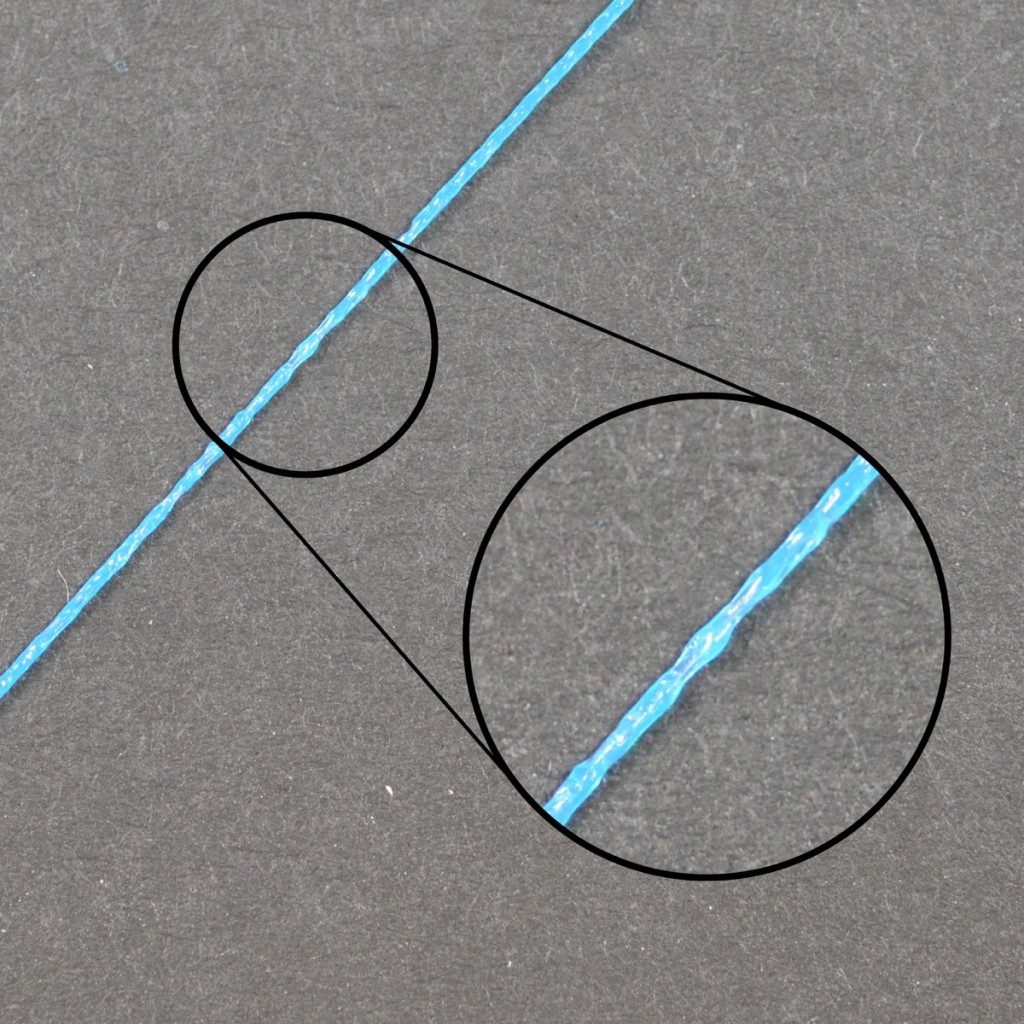

Each layer of your 3D printed part is created using a combination of outline perimeters and infill. The perimeters trace the outline of your part creating a strong and accurate exterior. The infill is printed inside of these perimeters to make up the remainder of the layer. The infill typically uses a fast back-and-forth pattern to allow for quick printing speeds. Because the infill uses a different pattern than the outline of your part, it is important that these two sections merge together to form a solid bond. If you notice small gaps between the edges of your infill, then there are several settings you may want to check.

Common Solutions

Not enough outline overlap

Simplify3D includes a setting that allows you to adjust the strength of the bond between the perimeter outlines and the infill. This setting is called the “Outline overlap” and determines how much of the infill will overlap with the outline to join the two sections together. This setting can be found by going to “Edit Process Settings” and selecting the Infill tab. The setting is based on a percentage of your extrusion width, so that it easily scales and adjusts for different nozzle sizes. For example, if you are using a 20% outline overlap, it means that the software will instruct the printer so that the infill overlaps with 20% of the inner-most perimeter. This overlap helps to ensure a strong bond between the two sections. As an example, if you were previously using an outline overlap of 20%, try increasing that value to 30% to see if the gaps between your perimeters and infill disappear.

Printing too fast

The infill for your part is generally printed much faster than the outlines. However, if the infill is printed too fast, it will not have enough time to bond to the outline perimeters. If you have tried increasing the outline overlap, but you are still seeing gaps between your perimeters and infill, then you should try decreasing the print speed. To do this, click “Edit Process Settings” and select the Speeds tab. Adjust the “Default Printing Speed”, which controls the speed of any movements where the extruder is actively extruding plastic. For example, if you were previously printing at 3600 mm/min (60 mm/s), try decreasing that value by 50% to see if the gaps between your perimeters and infill disappear. If the gaps are no longer present at the lower speed, gradually increase the default printing speed until you find the best speed for your printer.