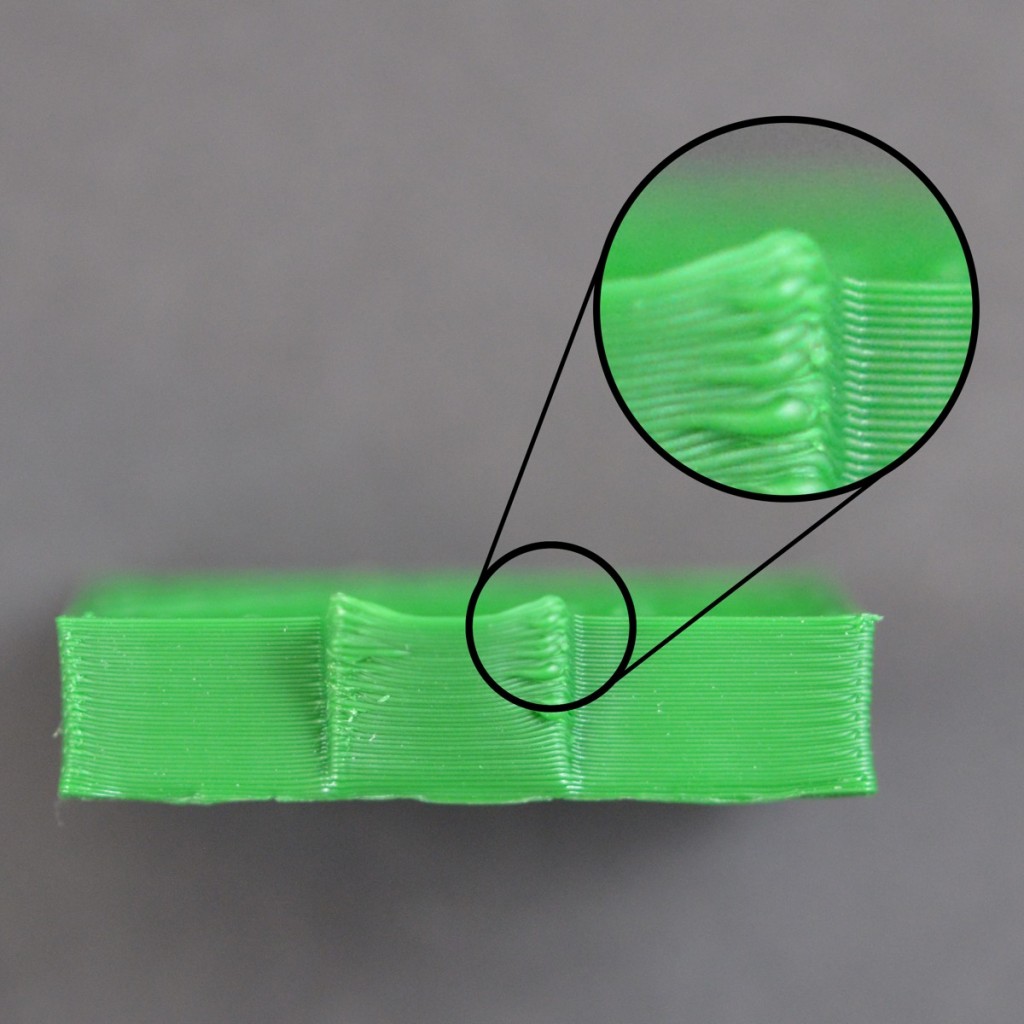

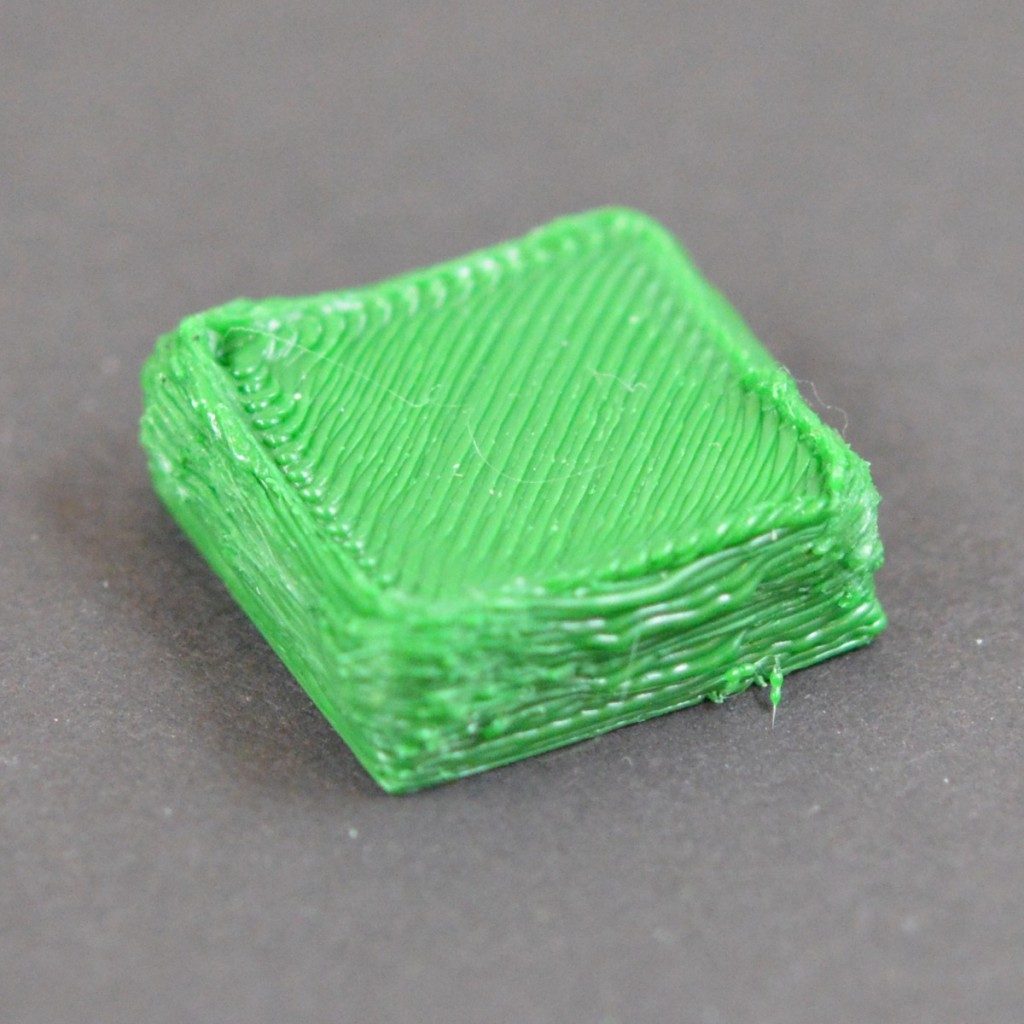

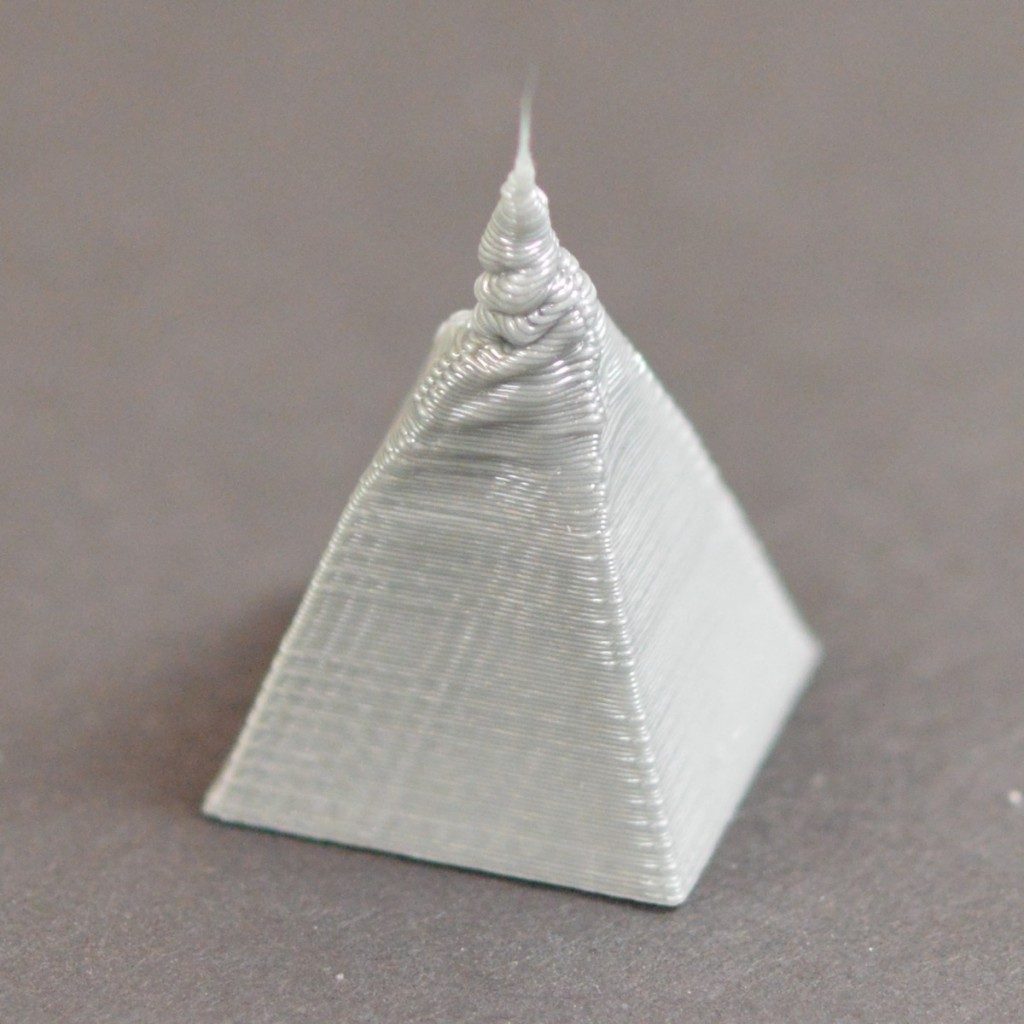

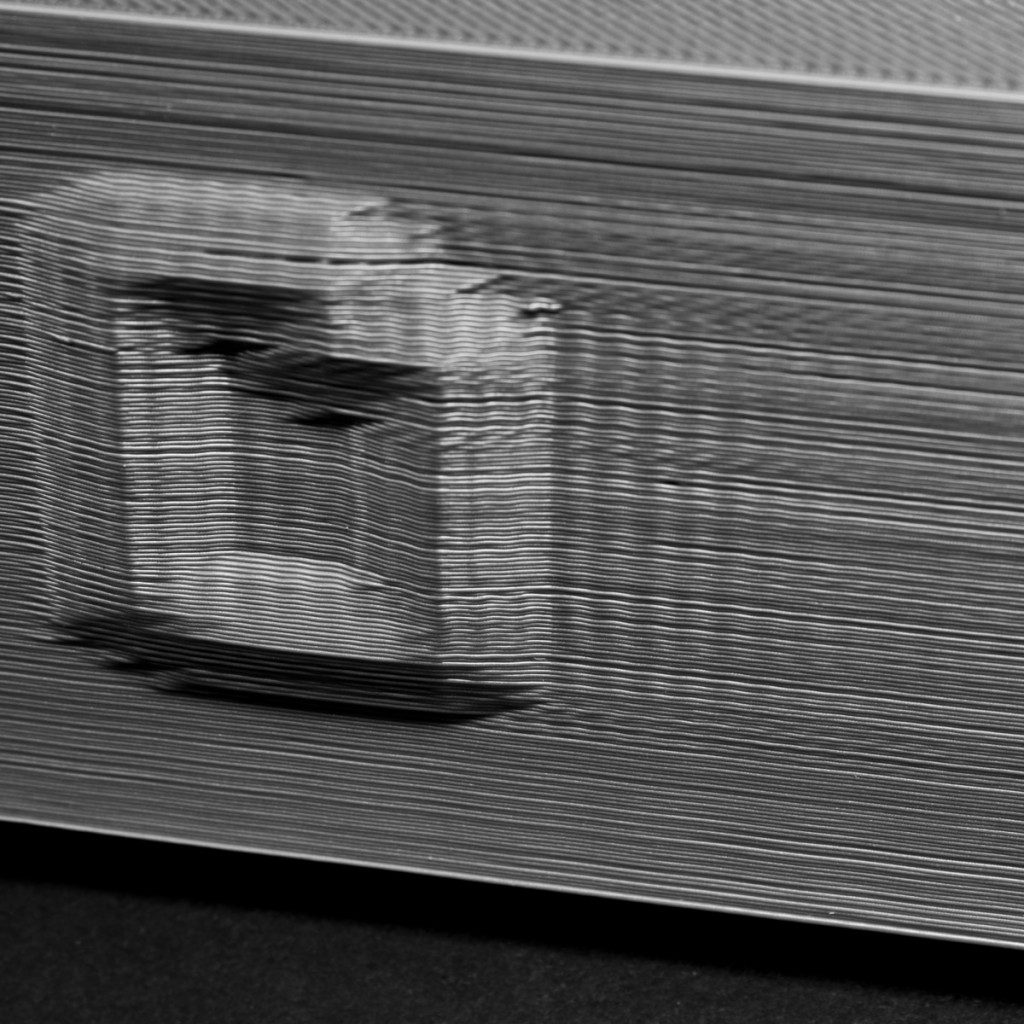

Curling or Rough Corners

If you are seeing curling issues later on in your print, it typically points to overheating issues. The plastic is extruded at a very hot temperature, and if it does not cool quickly, it may change shape over time. Curling can be prevented by rapidly cooling each layer so that it does not have time to deform before it has solidified. Please read the Overheating section for a more detailed description of this issue and how to resolve it. If you are noticing the curling at the very beginning of your print, please see the Print Not Sticking to the Bed section to address first layer issues.