Restoring Museum Relics with 3D Printing

Archeologist Néstor Marqués is on the cutting edge of restoration, using 3D printing technology as a way to help people interact with ancient history. Starting in 2012, Néstor began experimenting with ways to combine his love of technology with his passion for archeology. This resulted in the ability to restore ancient artifacts in a completely new way. Today, Nestor uses 3D printing to design full-size replicas of ancient artifacts for museums looking to create a more tactile experience for their guests.

Specializing in the Roman World and cultural dissemination, Néstor travels the world creating virtual museums and developing educational resources and strategies for museums and institutes. His work has led to the restoration of over 50 display pieces in 2018 alone.

Replicating Ancient Artifacts

After 3D printing his first model in 2012, Néstor immediately recognized its potential. “3D printing allowed me to physically reproduce any object that I had designed or virtualized in a simple, cost-effective way. It eliminated the need to rely on large industries, and I quickly realized the impact this technology could have, not only for museums and heritage but even for my daily life!”

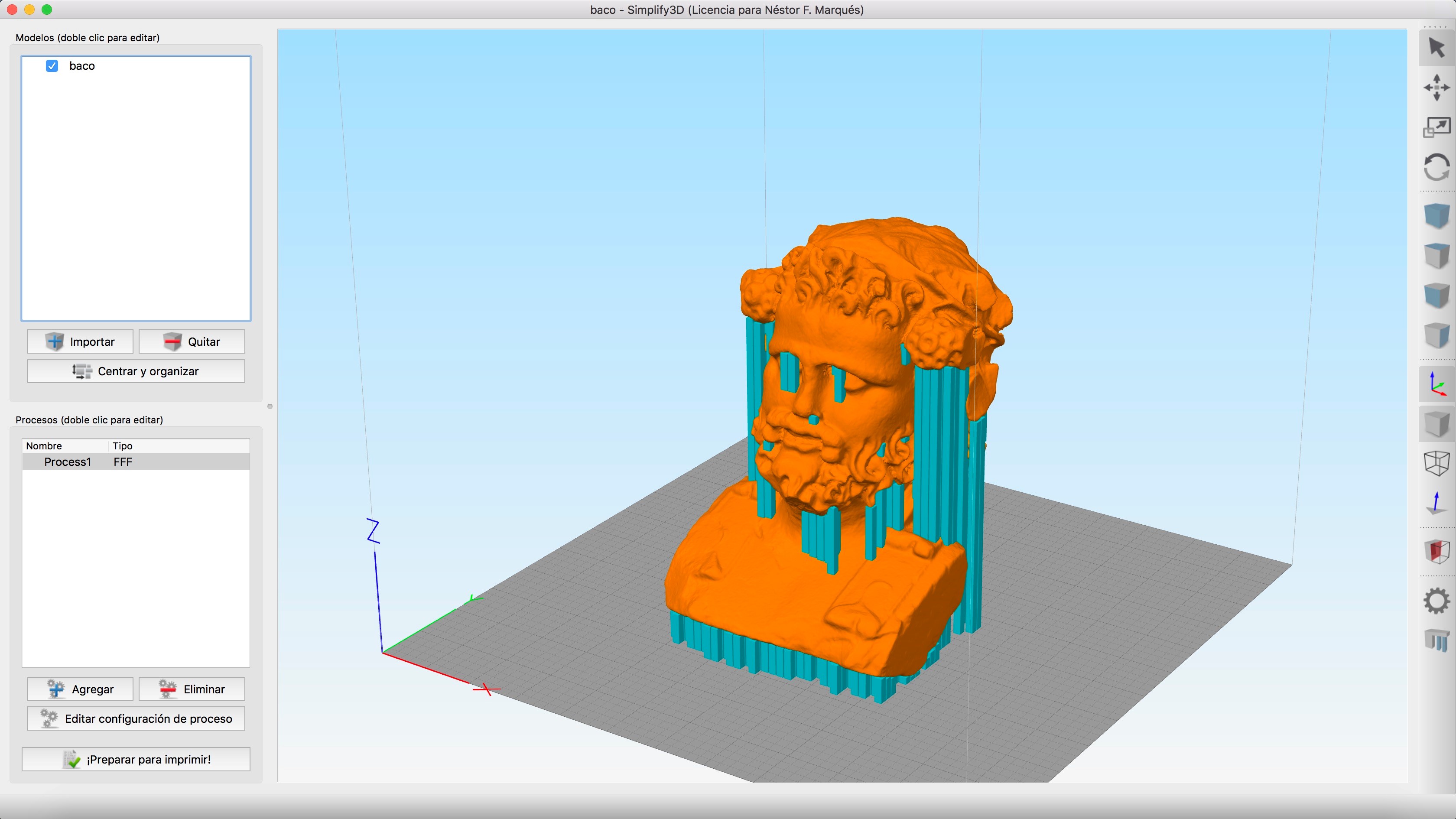

Nestor uses a technology called photogrammetry to first scan relics to create virtualizations and 3D models. These scans can then be rendered into a solid, three-dimensional model and 3D printed. His 3D printing software of choice is Simplify3D, “I started using Simplify3D to slice my models because I was tired of other common slicers. I needed a versatile, fast tool which had the quality and reliability I require for my work with museums. After using it for a few weeks, I would never go back to other slicers. Simplify3D is both easy to use and powerful. It allows me to repair, inspect, and configure every detail of my prints just the way I want.”

Nestor uses a technology called photogrammetry to first scan relics to create virtualizations and 3D models. These scans can then be rendered into a solid, three-dimensional model and 3D printed. His 3D printing software of choice is Simplify3D, “I started using Simplify3D to slice my models because I was tired of other common slicers. I needed a versatile, fast tool which had the quality and reliability I require for my work with museums. After using it for a few weeks, I would never go back to other slicers. Simplify3D is both easy to use and powerful. It allows me to repair, inspect, and configure every detail of my prints just the way I want.”

Néstor uses a variety of tools in Simplify3D to make his printing process more efficient, but his favorite is “the ability to use several processes and configurations in a single print.” This feature allows him to adjust the layer height throughout his model depending on the resolution required, significantly reducing the print time of large models while improving print quality for highly-detailed sections. Using these tools and strategies, he has replicated everything from small pieces of Roman pottery to full-scale busts and statues. After he has printed the replicas, Néstor then finishes and paints the replicas to make them look exactly like the originals. Recently he scanned a 2,300 year old statue, and 3D printed it in its actual size, over four feet tall! It was printed in twenty-one pieces, glued together over a base structure, and painted to resemble the original statue. He printed this replica for Spanish museum, Vilamuseu, to use while the original stayed at its current home, the National Archaeological Museum of Spain.

Néstor uses a variety of tools in Simplify3D to make his printing process more efficient, but his favorite is “the ability to use several processes and configurations in a single print.” This feature allows him to adjust the layer height throughout his model depending on the resolution required, significantly reducing the print time of large models while improving print quality for highly-detailed sections. Using these tools and strategies, he has replicated everything from small pieces of Roman pottery to full-scale busts and statues. After he has printed the replicas, Néstor then finishes and paints the replicas to make them look exactly like the originals. Recently he scanned a 2,300 year old statue, and 3D printed it in its actual size, over four feet tall! It was printed in twenty-one pieces, glued together over a base structure, and painted to resemble the original statue. He printed this replica for Spanish museum, Vilamuseu, to use while the original stayed at its current home, the National Archaeological Museum of Spain.

Impact of 3D Printing in Museum and Research Industries

Néstor believes that advancements in 3D technology are creating a revolution for museums. “Thanks to photogrammetry, we can preserve every heritage object in 3D and make it available to researchers and the general public. 3D printing takes advantage of the 3D files to create perfect replicas of the objects or even resize them if the objects are so small that their details can’t be seen properly.”

Néstor believes that advancements in 3D technology are creating a revolution for museums. “Thanks to photogrammetry, we can preserve every heritage object in 3D and make it available to researchers and the general public. 3D printing takes advantage of the 3D files to create perfect replicas of the objects or even resize them if the objects are so small that their details can’t be seen properly.”

Sometimes artifacts need to travel for exhibits and research. Traveling with these delicate, ancient relics often incurs high costs and puts the antiques at considerable risk, requiring complicated logistics and planning. With 3D printing, exact replicas can travel cost efficiently to anywhere in the world without putting the originals at risk. Néstor predicts a “near future where we will be able to literally take the museum wherever we want.”

Sometimes artifacts need to travel for exhibits and research. Traveling with these delicate, ancient relics often incurs high costs and puts the antiques at considerable risk, requiring complicated logistics and planning. With 3D printing, exact replicas can travel cost efficiently to anywhere in the world without putting the originals at risk. Néstor predicts a “near future where we will be able to literally take the museum wherever we want.”

Because of the durability and low cost of 3D printed replicas, museums can allow their guests to touch the replicas, creating a new way of experiencing ancient artifacts. Néstor sees this as a big win for accessibility in museums. “Accessibility for disabled people is a great advantage of 3D printed replicas. Imagine a blind person in a museum. Everything is behind the glass, and they cannot touch anything, so they can’t enjoy. 3D printing ensures they get a great heritage experience by knowing they are touching an exact replica of the object.”

Current and Future Projects

In 2018 Néstor 3D printed and hand-painted more than 50 pieces for display rooms in several museums. He also has many projects planned for 2019, “This year I will work on more museum collections that will get the same technological and accessibility protocols, which is very exciting. I’ll also be doing some other big scanning and printing projects.” You can find many of Néstor’s models on Sketchfab or visit his virtual museum of the Roman World, Antigua Roma al Día. By combining his passions and creating his own path, Néstor has contributed to his field in groundbreaking ways.

At Simplify3D we love highlighting inspiring projects in our community! Have you created a new avenue in your industry or used 3D printing in a new or interesting way? Share your story with us at stories@simplify3d.com.