Simplify3D Version 4.0 Adds New Capabilities and Improved Quality

We’re extremely excited to announce Simplify3D Version 4.0! As our company enters its fifth year, this major update is one of our largest releases yet and implements many of the most popular feature requests that we have received from the community. New features in the software will provide even more control over the printing process and help unlock new capabilities from your 3D printer.

Variable Print Settings

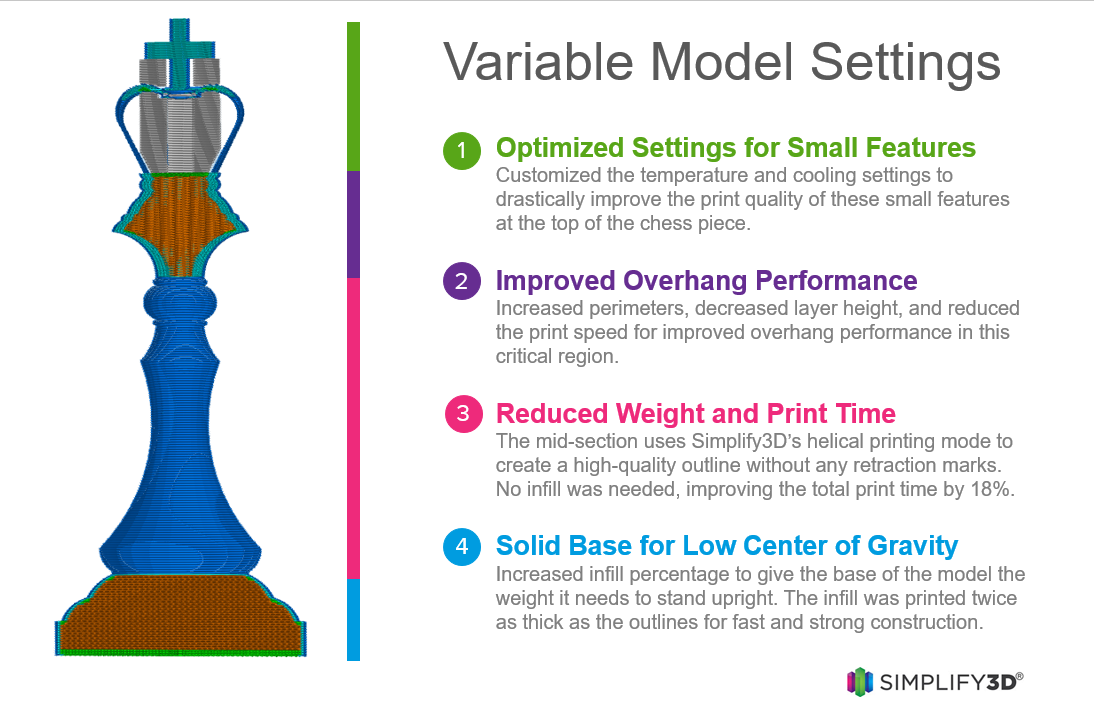

Experienced users understand improving your print quality is a result of optimizing the settings that are used during the printing process. Different sections of a model may require different settings to achieve the best results. Version 4.0 introduces the Variable Settings Wizard, which makes it incredibly easy to optimize the behavior in each section of your model.

Simplify3D has a unique ability to allow customers to change literally any setting they want for different sections of a model, unlocking new possibilities such as changing the mechanical properties of your model throughout the build. You could add strength or weight in one section, while optimizing another section to be light-weight or to achieve a faster manufacturing time. For example, the Chess Piece in the diagram below was printed with varying properties to improve the print quality in different sections and provide a lower center of gravity, all while still improving the overall print time by 22%.

Dynamic Feature Sizing

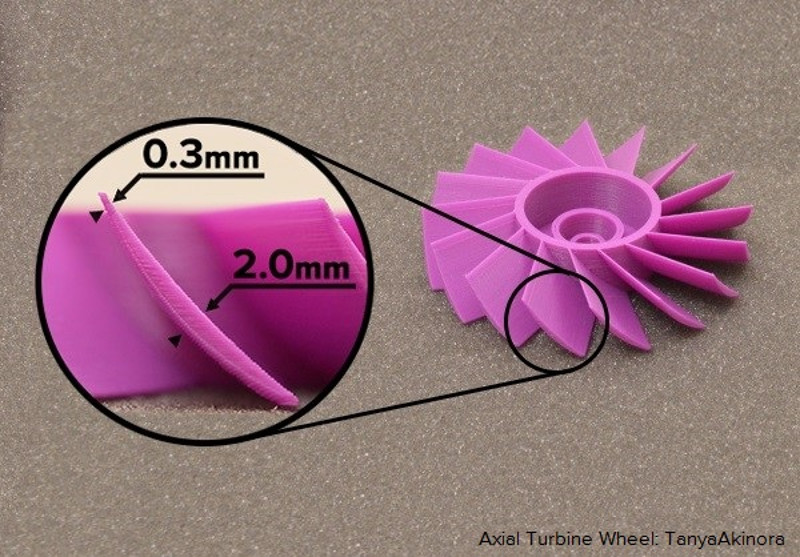

Many 3D printer owners know that printing small, delicate, or tapering areas on a model can be difficult, due to the fixed nozzle size on most FFF/FDM 3D printers. Many guidelines recommend creating models that are at least 1mm wide in all locations, but with Version 4.0 we are introducing new technology to greatly improve these capabilities. New functionality in the software will dynamically adjust the amount of plastic that is extruded from the nozzle to create smaller or larger extrusions depending on the shapes you are trying to print. This enables your printer to produce smaller and more accurate shapes than previously possible. The same technology has also been applied to the interior of the model, ensuring walls are properly sealed to improve the strength of critical components.

The fan blades in the photo below demonstrate this ability to dynamically adjust the flow, achieving a sharper leading edge that more closely matches the designer’s intent. In addition, the interior of these blades was perfectly filled to ensure a strong, robust print. This enables printing of many models that were not previously possible, so we can’t wait to see all of the new ways this technology will be used!

Improved Model Foundations

For more complex models, 3D printing success is frequently influenced by the foundational elements that stabilize a print during construction, such as supports, rafts, or brims. Version 4.0 includes improvements for this entire collection of foundational elements, starting with enhancements to the award-winning Simplify3D support structures. Several new features improve the ability of the support structures to stay anchored to the build platform, allowing even the tallest models to be fully supported through long build sequences. Other new features will allow customers to vary the density or material that is used for the top layers of the supports, near the surface of the part. This creates some unique possibilities, such as switching to a dissolvable support material near the part surface for easier removal.

Version 4.0 also includes a completely new raft design, offering the same break-away removal that customers love with Simplify3D support structures. Improved raft construction algorithms reduce the amount of filament that will be used and then discarded, often saving 50% of the filament and up to 40% of the print time that would have been allocated for the raft using previous methods. So whether you are printing rafts, supports, or brims, you can rest assured that all of these items have been improved in Version 4.0 to provide even better prints and easier post-print cleanup.

Many More Additions in Version 4.0

This release contains many more popular features requests from the community, so we truly appreciate your continued feedback and support. Our development constantly reviews the ideas that we receive to make sure that these suggestions are implemented into the product. We have already started working on Version 4.1, so let us know what you’d like to see next! We also want to thank many of our partners who helped make this release possible. Simplify3D has partnered with 3D printing companies in over 30 countries to make sure that our software supports the latest advancements in 3D printing technology. Version 4.0 continues to support the next generation of 3D printing hardware so that you can use the software with any machine you choose to purchase in the future.

This post is only a small preview of everything that was added in Version 4.0. Click the link below to see a complete list of new features along with instructions on how to download the latest release!