Nylon

Nylon is a tough and semi-flexible material that offers high impact and abrasion resistance. It is an ideal choice for printing durable parts.

Overview

Nylon (a.k.a. Polyamide) is a popular material in the plastics industry, known for its toughness and flexibility. Nylon filaments typically require extruder temperatures near 250 ºC, however, some brands allow printing at temperatures as low as 220 ºC due to their chemical composition. Many printers do not include a hotend that can safely reach 250 ºC, so these lower-temperature versions can be useful and potentially save you from needing to upgrade your hotend. One big challenge with Nylon filaments is that they are hygroscopic, which means they readily absorb moisture from their surroundings. Printing Nylon after it has absorbed moisture will lead to several print quality issues, thus filament storage becomes very important and requires special attention.

Pros

- Tough and partially flexible

- High impact resistance

- No unpleasant odor while printing

- Good abrasion resistance

Cons

- Prone to Warping

- Air-tight storage required to prevent water absorption

- Improperly dried filaments can cause printing defects

- Not suitable for moist and humid environments

Hardware Requirements

Before 3D printing with Nylon make sure your 3D printer meets the hardware requirements listed below to ensure the best print quality.

Best Practices

These tips will help you reduce the chances of common 3D printing issues associated with Nylon such as warping and moisture absorption.

Filament Storage

One of the challenging aspects of using Nylon is the need for a special storage system. Unlike other filaments, you cannot keep the filament spool exposed to the air for extended periods of time. Nylon easily absorbs moisture from the environment. Printing the moist filament will result in print quality issues like a foggy rough surfaces or even tiny holes or bubbles on the exterior. These printing issues can also significantly decrease the strength and performance of the printed parts. The typical solution for this issue is to remove the Nylon spools from the printer once you are done, and store the spools in an air-tight container along with some desiccants to remove the moisture from within. If you do not want to constantly mount and remove your filament spool, there are also commercially available storage containers that will keep the filament dry, while allowing it to feed out of a hole in the container.

Use an Enclosure to Prevent Warping

Some high-temperature Nylons are prone to warping due to the large temperature change between the extruded plastic and the ambient environment. Heated beds can reduce the warping to a some extent, but using a printer that has a heated chamber or enclosure would be the ideal solution. Keeping the air around your part at a temperature of about 45 ºC will help eliminate warping by reducing this temperature variation. If your printer doesn’t include a heated chamber and you aren’t able to add an enclosure, there are other tips that you can use to help prevent warping. Our Print Quality Guide has an entire section devoted to this issue which summarizes other common techniques: How to Prevent Warping.

Using Brims and Rafts

In situations where adding an aftermarket enclosure may not be an ideal option, consider using a brim or a raft to help with first layer adhesion. Adding a brim will add several loops around the bottom layer of your model, creating a larger surface area to hold down the edges of your print. Version 4.0 of Simplify3D introduced a completely new raft design that can also be very useful if you continue to have printing difficulties. For more information on the differences between rafts, skirts, and brims, please consult our in-depth article on this topic.

Pro-Tips

- If you do not have air-tight containers for storing your filament, you can dry the spools just before use by running them through a Food Dehydrator. A few hours in this device will dry the filament significantly.

- Nylon makes a good filament for cleaning your nozzle. You can use a technique called “cold pulling” where you allow the Nylon to bond to debris within the nozzle, and then after it partially cools, you pull the filament (and debris) out of the hotend.

Get Started with Nylon

Nylon can be a great material once you have mastered the basics. Once you’re ready to give it a try, here are some tips to help you get started.

Common Applications

- Plastic Gears

- Screws, nuts, bolts

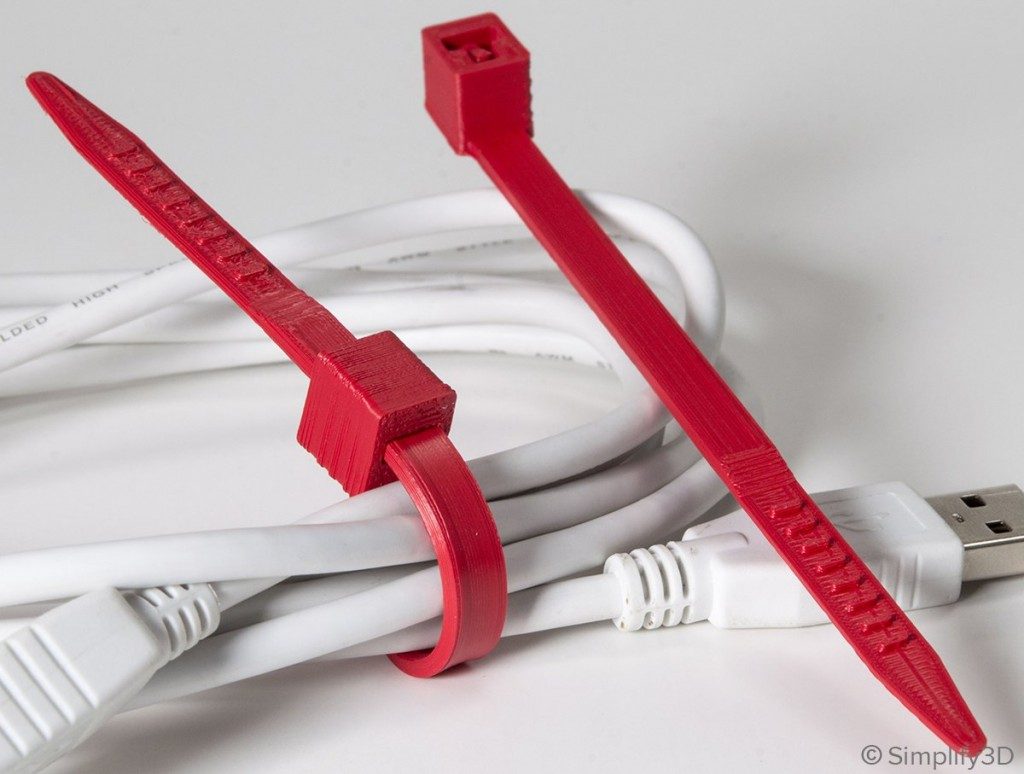

- Cable ties

Sample Projects

Popular Brands

- Taulman Nylon

- Matterhackers PRO Nylon

- HobbyKing Nylon

- GizmoDorks Nylon

How does Nylon compare to other popular materials?

Click below to view our extensive Properties Table with a complete side-by-side comparison.