PETG

PET and PETG filaments are known for their ease of printability, smooth surface finish, and water resistance.

Overview

PETG is a Glycol Modified version of Polyethylene Terephthalate (PET), which is commonly used to manufacture water bottles. It is a semi-rigid material with good impact resistance, but it has a slightly softer surface which makes it prone to wear. The material also benefits from great thermal characteristics, allowing the plastic to cool efficiently with almost negligible warpage. There are several variations of this material in the market including PETG, PETE, and PETT. The tips in this article will apply to all of these PET-based filaments.

Pros

- Glossy and smooth surface finish

- Adheres well to the bed with negligible warping

- Mostly odorless while printing

Cons

- Poor bridging characteristics

- Can produce thin hairs on the surface from stringing

Hardware Requirements

Before 3D printing with PET / PETG make sure your 3D printer meets the hardware requirements listed below to ensure the best print quality.

Best Practices

These tips will help you reduce the chances of common 3D printing issues associated with PET / PETG such as stringing, oozing, and poor bed adhesion.

Invest In a Good Build Surface

Some 3D printers come with a glass bed or blue painter’s tape installed on the bed. Although these surfaces might work fine for PETG, we recommend using a heated build platform for best results. The heated bed can significantly improve the first layer adhesion, making things much easier for future prints. Many of these heated beds come with a glass surface, allowing you to print directly on the bed without needing to apply any additional layers of tape or glue.

Calibrate Retraction Settings to Reduce Stringing

One of the few common issues that we see with PETG is stringing. These strings are thin hairs, similar to a spider web, that run between the different surface of your 3D print. Preventing these strings requires precisely calibrated retraction settings, so make sure to adjust your retraction distance and speed for the best results. Simplify3D also includes several useful features that can further reduce stringing. The first is called Coasting, which works by reducing the pressure in the nozzle right before the end of a segment. This way, when moving to the next segment, there is less pressure in the nozzle, so you are less likely to see stringing and oozing during that move. Another great option can be found on the Advanced tab of your Simplify3D process settings. By enabling the “avoid crossing outline for travel movements” option, the software will automatically adjust the travel movements of your print to stay on top of the interior of your model as much as possible. This means that the strings stay inside of your part where no one can see them, instead of being on the outside of your model. If you are looking for more tips to reduce stringing, we have an entire section dedicated to this issue on our Print Quality Guide: How to Reduce Stringing and Oozing.

Optimize Extruder Settings to Prevent Blobs and Zits

When 3D printing at higher temperatures associated with PETG, you may notice small blobs or zits on the surface of your model. These print defects typically occur at the beginning or end of each segment, where the extruder has to suddenly start or stop extruding plastic. There are several ways to eliminate these print defects such as enabling “Extra Restart Distance” or “Coasting” options located in the Extruder tab. Simplify3D also includes an option to perform a dynamic retraction, where the filament is retracted while the extruder is still moving. This completely eliminates blobs that are typically formed from a stationary retraction. To learn more about these features and other tips for reducing blobs on the surface of your print, please refer to our Print Quality Guide.

Pro-Tips

- The glossy surface of PETG is especially useful when using rafts. The part separates easily from the raft and maintains a clean surface finish.

- Try disabling your part cooling fan for the first few layers of the print to prevent warping. This trick especially works well for larger prints.

Get Started with PET / PETG

Now that you are ready to start printing with PET / PETG, here are a few ideas to help you get started – from common applications to popular filament brands.

Common Applications

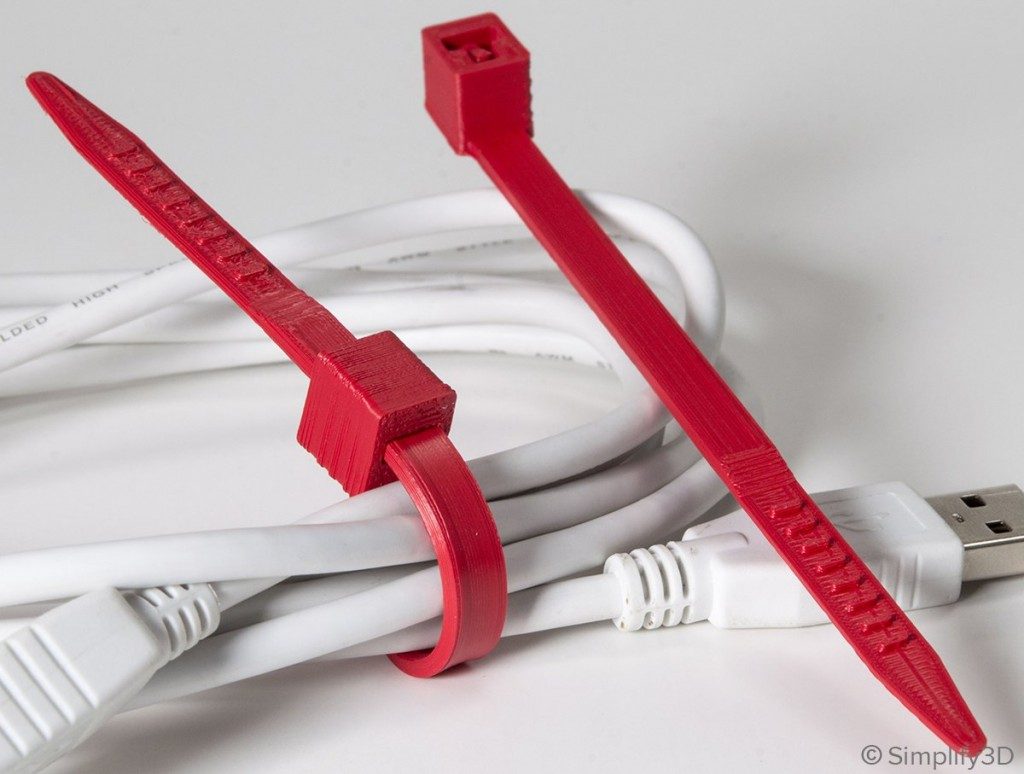

- Water proof applications

- Snap fit components

- Planter Pot

Sample Projects

Popular Brands

- ColorFabb PETG

- eSun PETG

- E3D Spoolworks Edge

- Hatchbox PETG

- HobbyKing PETG

Want to see how PET and PETG compare to other materials?

Click below to view our extensive Properties Table with a complete side-by-side comparison.