Polypropylene

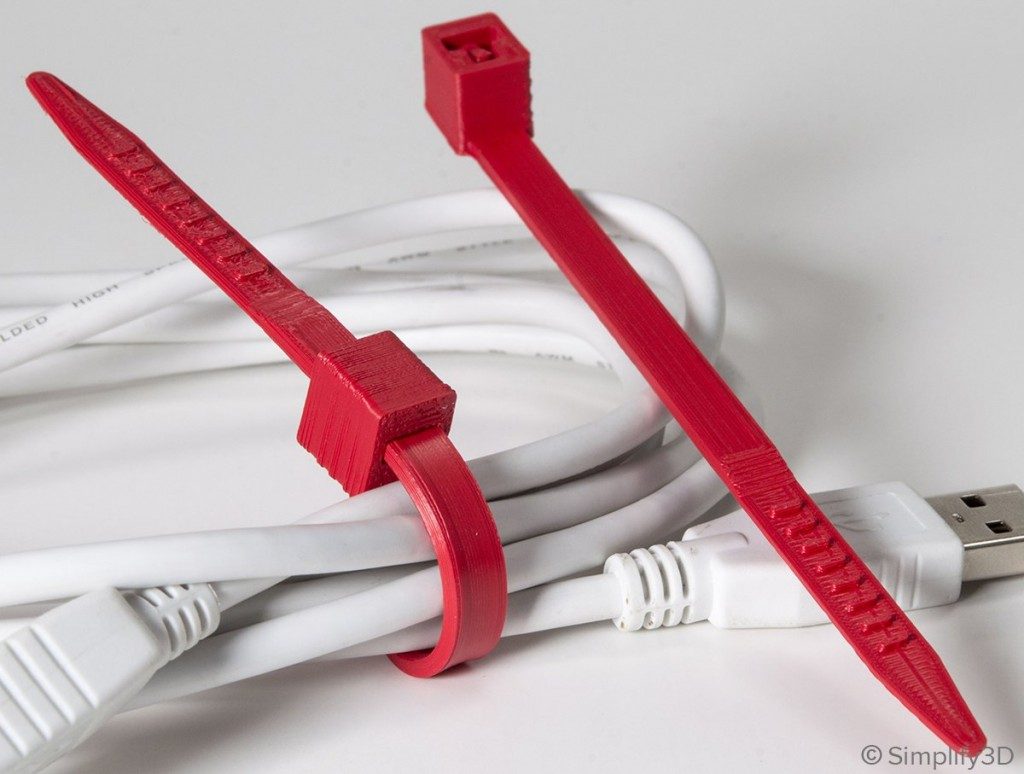

Polypropylene is great for high-cycle, low strength applications due to its fatigue resistance, semi-flexible, and lightweight characteristics.

Overview

Polypropylene is a semi-rigid and lightweight material that is commonly used in storage and packaging applications. The semi-crystalline structure of the material causes the 3D printed parts to heavily warp upon cooling, making it challenging to 3D print. Polypropylene is tough and has a good fatigue resistance making it ideal for low strength applications like living hinges, straps, leashes, etc. A few manufacturers have even created polypropylene blends that have improved toughness making it suitable for practical use. The tips in this article will cover all the different types of polypropylene filaments available for 3D printing.

Pros

- Good impact and fatigue resistance

- Good heat resistance

- Smooth surface finish

Cons

- Heavy warping

- Low strength

- Difficult to adhere to bed and other adhesives

- Expensive

Hardware Requirements

Before 3D printing with Polypropylene make sure your 3D printer meets the hardware requirements listed below to ensure the best print quality.

Best Practices

These tips will help you reduce the chances of common 3D printing issues associated with Polypropylene such as warping and poor bed adhesion.

Choosing the Right Build Surface

Finding a good build surface can be very challenging when you need to print with Polypropylene. The low surface energy of polypropylene makes it extremely difficult to get good bed adhesion even with heated beds. We have found that polypropylene adheres well only to itself. Thankfully, packaging tape is a readily available surface that is also Polypropylene based, so it can be a great option. A thick strip of packing tape along with a heated bed can greatly improve the success of your first layer with this material. Some packing tapes melt around 90 ºC so it is important to keep the heated bed at a temperature slightly less than the melting point of the tape.

Use Rafts to Protect the Base Layer

Polypropylene prints can sometimes bond too well to the packaging tape on the surface of your bed, which makes it hard to separate the tape from the finished part once the print is complete. This happens because the high temperature of the heated bed allows the tape and the part to slightly fuse together. To avoid this, consider using a raft for your prints. The raft will act as an interface between the hot build surface and the bottom of your part. Once the print is complete, the raft can be discarded, so even if it partially fuses to the tape, this will not affect the final part. Version 4.0 of Simplify3D added several new features that use less time, less material, and create rafts that are far easier to remove, so consider giving this option a try if you are having trouble with the parts bonding to the tape.

Using a Heated Chamber or Enclosure

Having a good build surface may not be enough to prevent printing issues. Since we know that Polypropylene can warp quite heavily, it helps to have an enclosure of some sort to trap the heat around the print. Using a printer that has a heated chamber will help eliminate warping. Temperatures of 45-60 °C for a heated chamber will usually work well. Having a standard enclosure can also significantly control warping when used with the heated bed, since the bed will help heat the air around the part, which is contained by the enclosure. However, be careful to control the heated bed temperature to avoid damaging the packaging tape as mentioned above.

Pro-Tips

- Although Polypropylene can print well at low temperatures, printing at slightly higher temperatures in the range of 240 ºC can help with adhesion between layers to create a stronger part.

- Consider using a lower temperature for the first few layers of your print to prevent the part from fusing to the build surface.

Get Started with Polypropylene

Now that you understand some of the unique characteristics of this material, you are ready to try your first print. We’ve included a few ideas below to help you get started.

Common Applications

- Living hinges

- Storage containers

- Watch Straps

Sample Projects

Popular Brands

- Ultimaker Polypropylene

- GizmoDorks Polypropylene

- Verbatim Polypropylene

How does Polypropylene compare to other materials?

Click below to view our extensive Properties Table with a complete side-by-side comparison.