HIPS

HIPS is a lightweight material most commonly used as a dissolvable support structure for ABS models.

Overview

HIPS, or High Impact Polystyrene, is a dissolvable support material that is commonly used with ABS. When being used as a support material, HIPS can be dissolved in d-Limonene, leaving your print free of any markings caused by support removal. HIPS has many of the same printing properties as ABS, making it a logical dual extrusion partner. Not only is HIPS great for supporting your ABS prints, it’s also more dimensionally stable and slightly lighter than ABS, making it a great choice for parts that would end up getting worn out or used in applications that can benefit from the lighter weight.

Pros

- Low cost

- Impact and water resistant

- Lightweight

- Dissolvable by d-Limonene

Cons

- Heated bed required

- Heated chamber recommended

- High printing temperature

- Ventilation required

Hardware Requirements

Before 3D printing with HIPS make sure your 3D Printer meets the hardware requirements listed below to ensure the best print quality.

Best Practices

These tips will help you reduce the chances of common 3D printing issues associated with HIPS such as warping and poor bed adhesion.

Invest in a Good Build Surface

Kapton tape can be applied on top of your heated build platform, creating an ideal surface for HIPS to adhere to. Each layer of Kapton tape is about 0.1mm thick, so make sure to account for this in your first layer settings. You can make this adjustment in Simplify3D by increasing the global Z-axis offset on the G-Code tab of your process settings. PET sheets can also be applied over a glass bed to greatly enhance the adhesive properties while keeping the surface finish smooth. These solutions will all help to mitigate warping from your HIPS prints. If you need more suggestions on how to improve the bed adhesion, we have a section on our Print Quality Guide dedicated to this issue: How to Improve First Layer Adhesion.

Print with a High Ambient Temperature

To keep HIPS from contracting rapidly, you can try to increase the temperature surrounding the 3D printed part. This can be accomplished by enclosing the build environment and allowing the heated bed to slowly heat the air to the desired temperature. Some newer printers may actually include a heated chamber out-of-the-box which makes this process even easier. If you aren’t able to enclose the printer’s build volume on your own, you can also try using an ooze shield in Simplify3D, as this will create a shell that encases your model, allowing the air within that shell to stay at a higher temperature. This shield can also act as a wind block to keep colder air from rapidly cooling your freshly extruded plastic.

Adjust Settings to Prevent Layer Separation

Printing with HIPS can require some extra care to ensure that each layer of the print is securely bonded to the prior layer. Otherwise, you may notice splitting or cracking between layers. To improve the bonding between layers, consider lowering your layer height or increasing the extruder temperature. Both of these changes will help improve the adhesion between layers. If you want more information on how to combat this issue, please refer to our Print Quality Guide which contains an entire section dedicated to this issue: Layer Separation and Splitting.

Pro-Tips

- Some HIPS filaments include additives that make the filaments easier to print, but these same additives can frequently make the material harder to dissolve and remove if you plan to use HIPS as a support material.

- To improve bed adhesion, consider using an ABS slurry. This mixture can be created on your own by mixing pieces of ABS filament with acetone and then applying the mixture to your print bed surface.

Get Started with HIPS

Congratulations you are now ready to start 3D printing with HIPS! Get project ideas from our common applications and sample projects and check out the popular HIPS filament brands below.

Common Applications

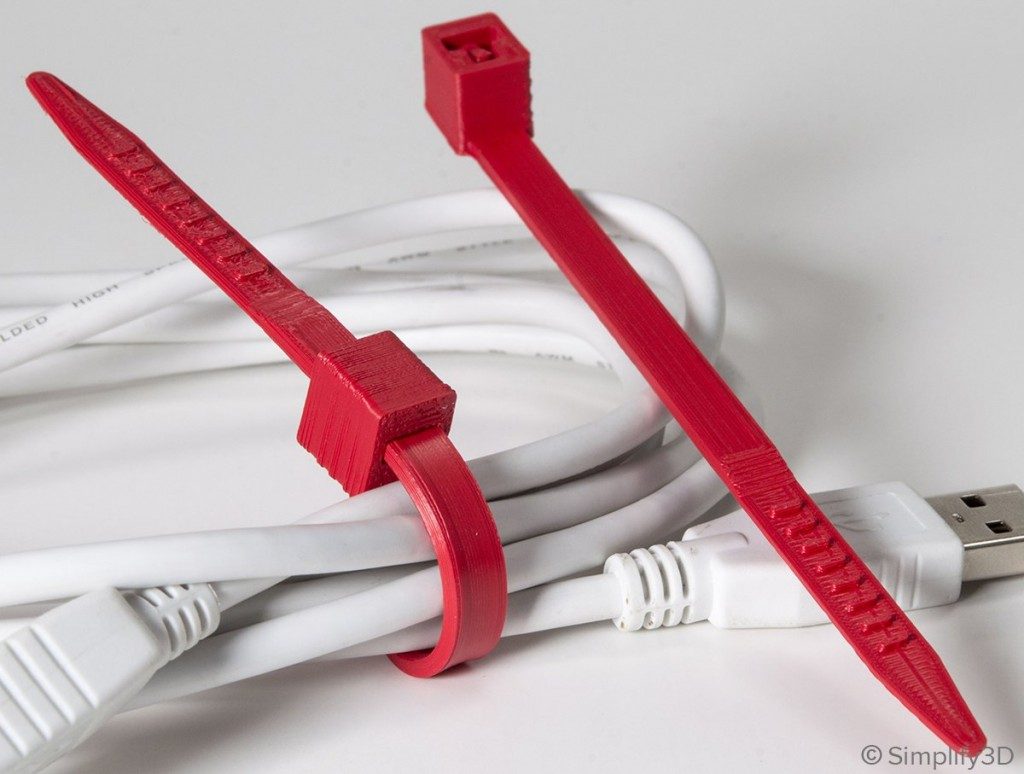

- Dissolvable Support Material for ABS

- Cosplay & Wearables

- Protective Cases

Sample Projects

Popular Brands

- GizmoDorks HIPS

- FormFutura EasyFil HIPS

- Matterhackers HIPS

- eSun HIPS

How does HIPS compare to other materials?

Click below to view our extensive Properties Table with a complete side-by-side comparison.