Process System Improvements

Variable Print Settings

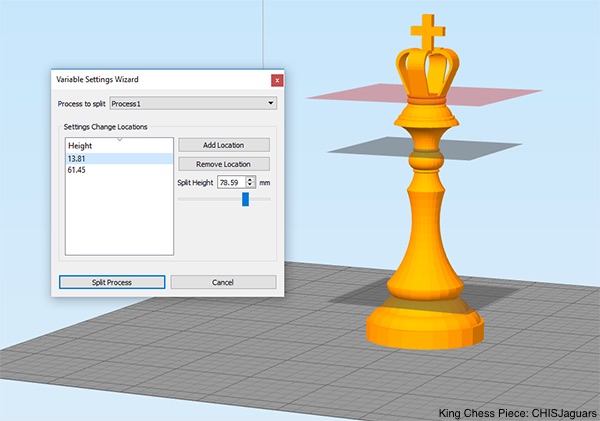

The new Variable Settings Wizard gives you the power to customize any setting that you want for different regions of your model. You can customize the print quality for different features, or even change the mechanical properties of the part unlocking a whole new world of possibilities!

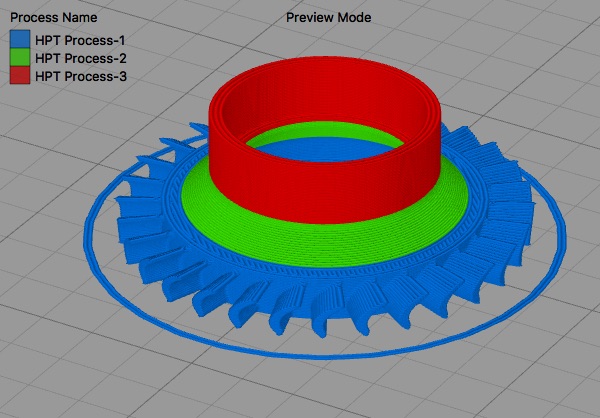

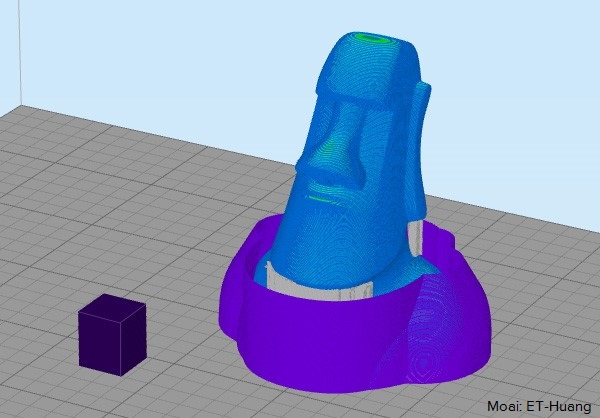

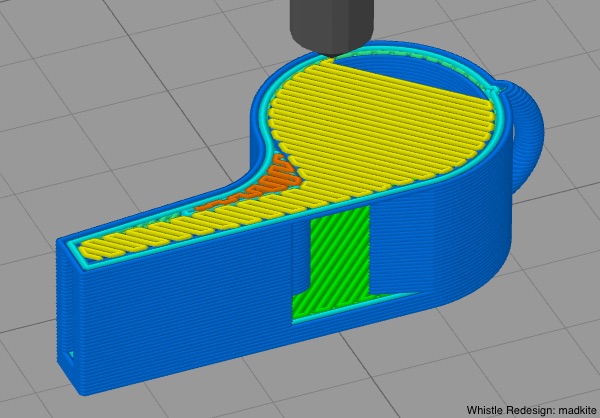

Preview your Processes

The interactive print preview has now been updated to include more information about which exact process was used to create different parts of your model. This makes it easy to verify the exact settings that were used for different sections of your build.

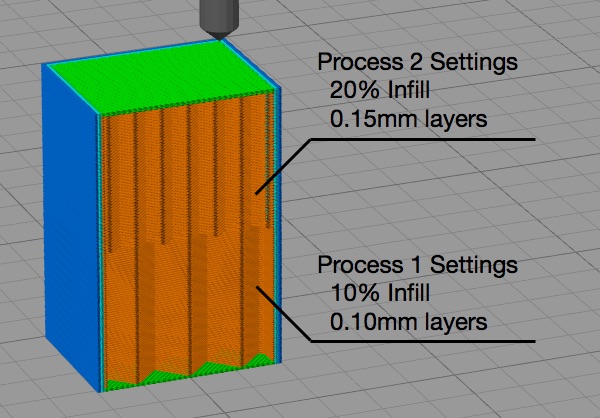

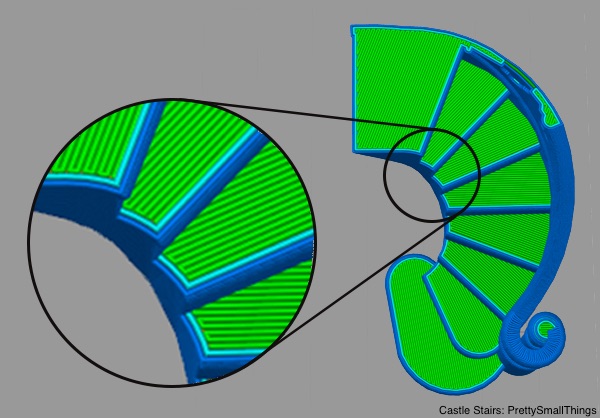

Seamless Process Transitions

As you change settings for different regions of your model, Simplify3D will automatically create a seamless transition between these settings. Whether you’re changing the layer height, infill, or anything else, the software ensures a smooth transition without extra solid layers or Z-scars.

Drag-and-Drop Reordering

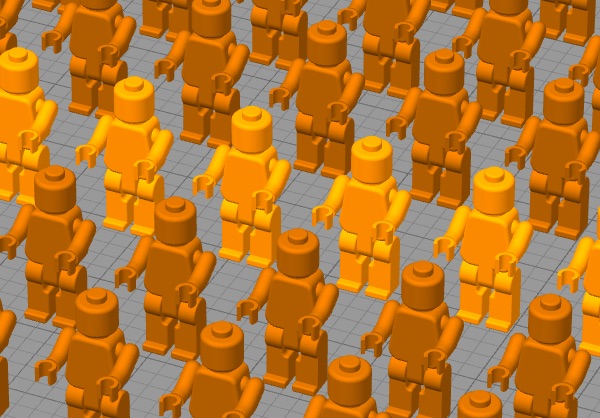

If you are printing multiple parts on the same build platform, you can now reorder your processes with simple drag-and-drop functionality. This allows you to customize the order of how the parts will be printed, which becomes very important for large prints!

Improved Sequential Printing

The sequential printing mode in Simplify3D allows you to finish printing a complete part before starting the next one. This greatly reduces the number of travel movements between parts, improving print quality. This mode now also supports multiple processes for the same model.

Dual Extrusion Customizations

The prime pillar and ooze shield have both been updated to better support multi-process prints. This adds new customization options for dual extrusion such as limiting the height of the prime pillar and ooze shield, saving time and material when these items are no longer needed.

New Options for Thin Walls and Gaps

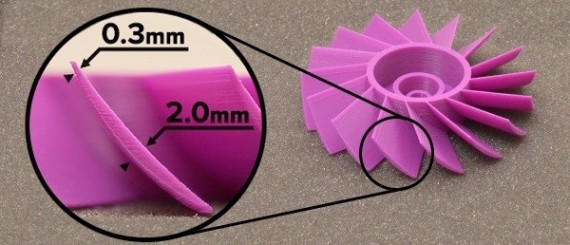

Variable Extrusion Sizing

New functionality in Simplify3D will automatically adjust the amount of plastic that is extruded from the nozzle to create smaller or larger extrusions depending on the shapes you are trying to print. This is extremely helpful for thin or tapering shapes, allowing you to print new features that were not previously possible with a fixed extrusion size.

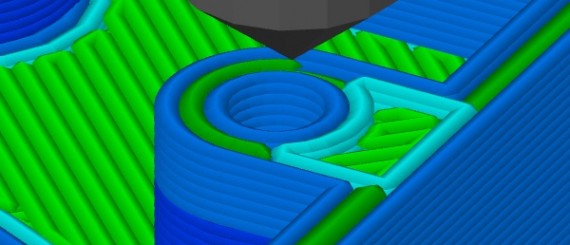

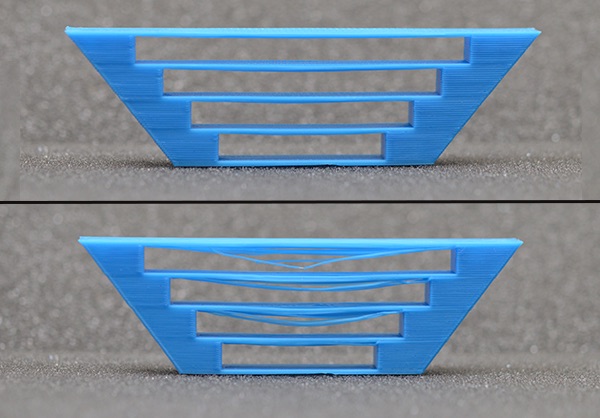

Dynamic Gap Fill

Thin walls and gaps can now be filled with a single dynamic extrusion that is automatically adjusted to fill the available space. Even if the thickness of these walls are constantly changing, the software will ensure the gaps are perfectly filled adding strength to your model’s interior. This also provides a significant print speed improvement versus previous gap fill methods.

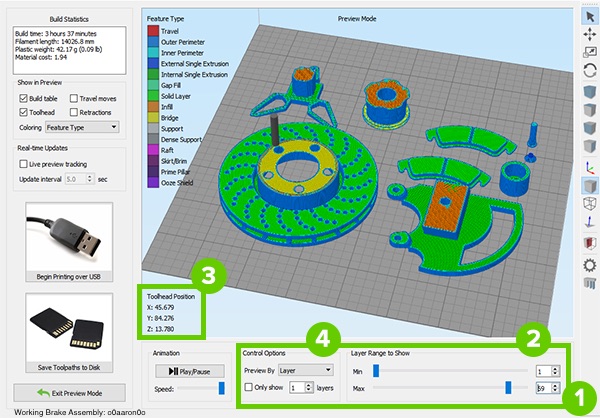

Enhanced Preview Controls

Simplify3D offers a unique interactive print preview that allows you to simulate your print exactly as it will happen on your 3D printer. You can watch the toolhead as it lays down each individual line of plastic, giving you an unprecedented level of insight into how your 3D printer will behave. With Version 4.0, we have improved the controls that you use to interact with the preview, making it faster and easier to spot issues that may affect your prints.

Keyboard Scrolling – The keyboard up/down keys ![]() can now be used to easily move through individuals lines or layers of your print.

can now be used to easily move through individuals lines or layers of your print.

Jump to Location – New controls allow you to jump to an exact line or layer number to quickly examine a specific point in time. This makes it much easier to navigate to different sections of your print.

Position Readout – The XYZ position of the tool head is now displayed in the print preview, allowing you to verify the exact Z-height or XY location where an event occurs.

Range Controls – New options allow you to limit the number of layers or lines that are shown in the preview. For example, if you know an issue occurred somewhere towards the end of your print, you can easily restrict the preview to only showing the last 20 layers.

“It’s slicer software for 3D printing – Yes, but on steroids!” – F. Grazier

Keep scrolling to learn more about Simplify3D 4.0…

The Best Supports Just Got Better

Strong Foundations

Several new features have been added to improve the adhesion between the bottom of your supports and the build platform. This can be particularly helpful for tall prints, where the supports need to be securely anchored to the bed to ensure they stay attached for the entire print.

- Solid Base Layers – This new option allows you to specify the number of solid layers at the base of your supports. These solid layers greatly increases the connection between the supports and the bed, while still allowing you to use sparse fill for the majority of the supports.

- Brim for Supports – Simplify3D now allows adding a brim around your support structures, which adds even more surface area to hold down the edges of your supports. Use this in combination with the solid support base layers for an incredibly strong hold!

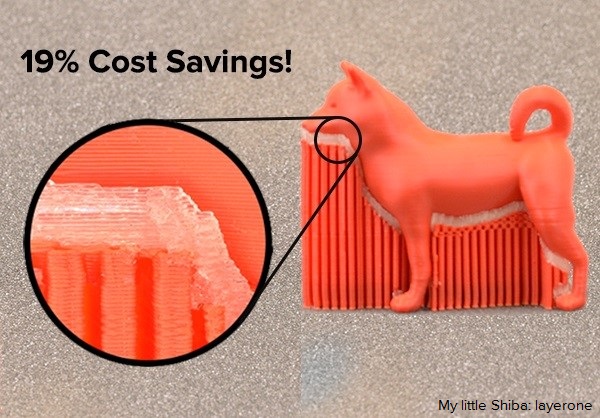

Optimize your Soluble Supports

Simplify3D includes a feature called Dense Supports, which will vary the density of your support structures near the surface of your part. This can provide a better foundation for your model, improving the print quality while still saving valuable amounts of material. Version 4.0 takes this one step further by giving you the ability to control the materials that are used for the different sections of your supports, allowing you to optimize the results even further.

In the example above, we were able to use these features to create a high quality print while saving over 18% on the cost of the materials. We printed the majority of the supports with a very sparse 20% fill using our inexpensive PLA material. In the last few layers of our supports near the surface of the part, we switched to a dense 70% fill with PVA, a water-dissolvable material. This allows you to optimize many aspects of your supports, and the savings quickly add up!

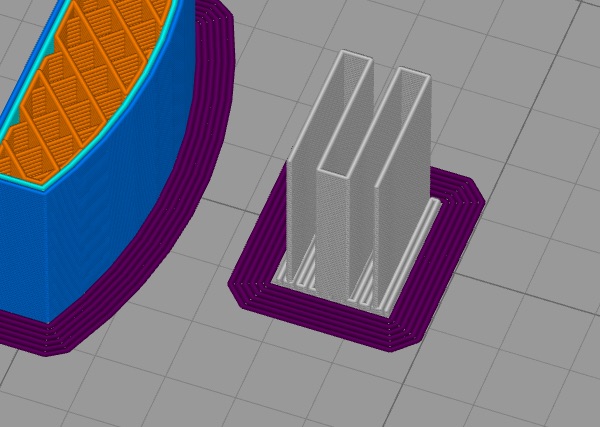

Smarter Break-Away Rafts

New Breakaway Raft Design

Simplify3D is well known for providing support structures that easily separate from your model, and we wanted to bring this same level of performance to the the raft. Version 4.0 includes a completely new raft design that allows for easy break-away removal, while still ensuring a strong foundation for your parts. We have also added new speed settings that can further customize the adhesion between the raft and your part.

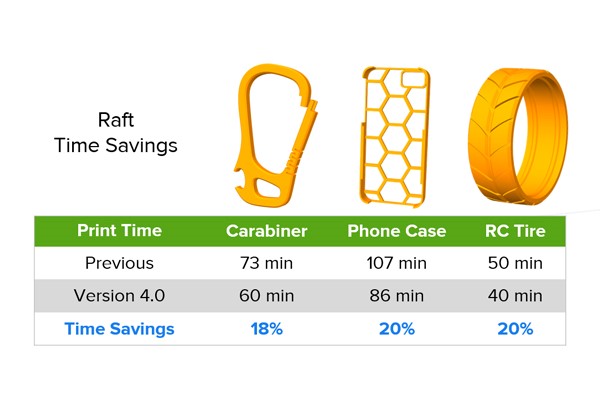

Improved Raft Construction

Along with a new design for the rafts, we have also optimized the actual placement and sizing of the rafts to ensure they are only used in the areas where they are absolutely needed. After testing a wide variety of parts, this has been shown to provide a time savings of up to 20% versus previous methods, while still providing a secure foundation for the prints.

Other Popular Requests

Bridging Perimeter Options

New options to define the exact speed, flowrate, and temperatures that are used for the outlines of your bridging regions. Using these precise properties for your bridging perimeters can greatly improve your odds of success!

Bridging Angle Selection

Version 4.0 includes a new bridging algorithm that optimizes the fill direction for your bridging regions to maximize your chance of success. You can also specify a custom direction for these layers if you want to try your own approach.

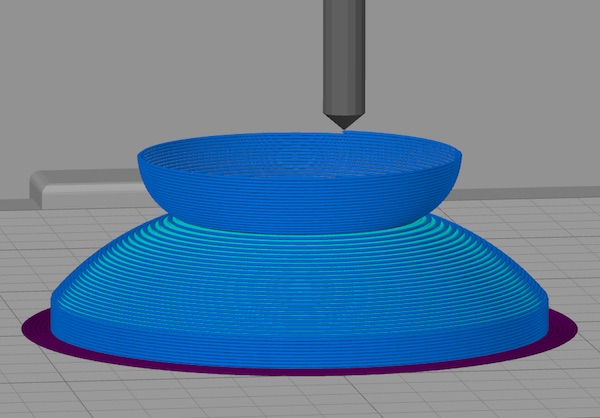

Multi-Process Vase Mode

Vase mode extrudes plastic in a continuous helical pattern to avoid any retractions or movements between layers. You can now use this high-quality printing mode with multiple processes, making it more accessible than ever.

External Fill Customization

Customize the fill direction for the top and bottom solid layers of your print. This can be used to optimize the mechanical strength of these outer layers or for aesthetic reasons to ensure the fill is oriented in a specific direction.

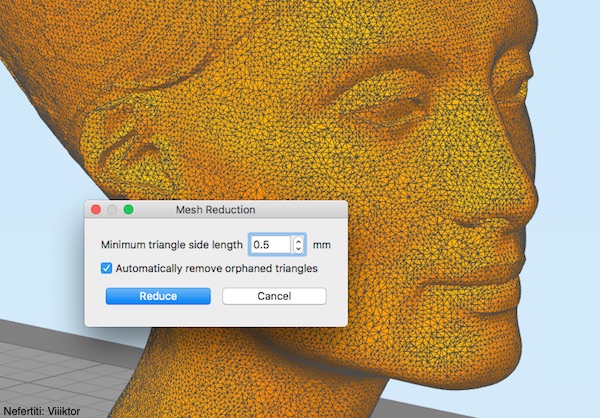

Improved Mesh Reduction

Simplify3D includes mesh analysis and repair tools to ensure your STL files are error-free and ready for printing. A vastly improved Mesh Reduction option allows you to quickly reduce the size of your models for easier processing.

And Much More…

Version 4.0 also includes many optimizations and bug fixes identified by the community. Our team constantly reviews your feedback to help make Simplify3D the best 3D printing software available!

Already have a Simplify3D account?

Download your free upgrade now